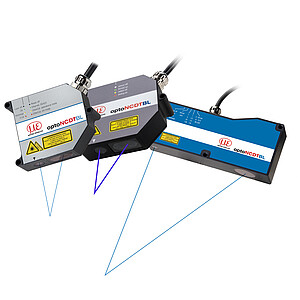

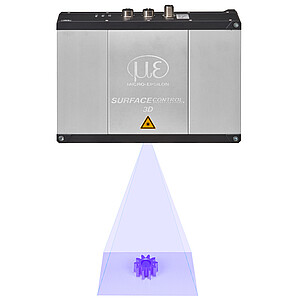

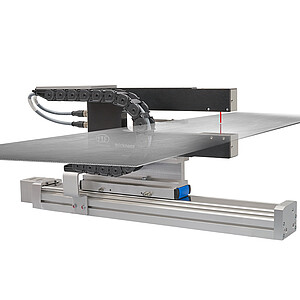

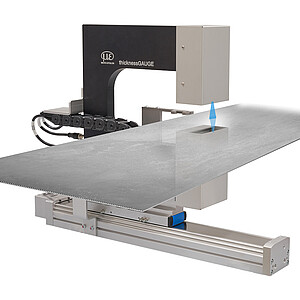

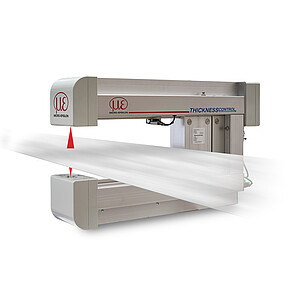

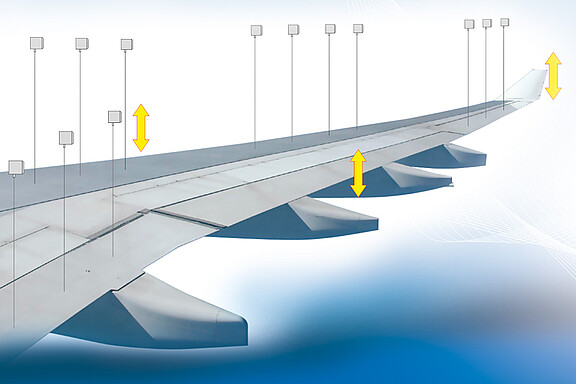

Deflection, deformation, waviness

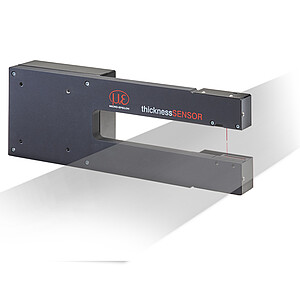

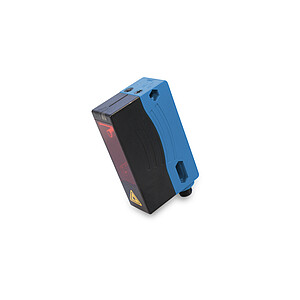

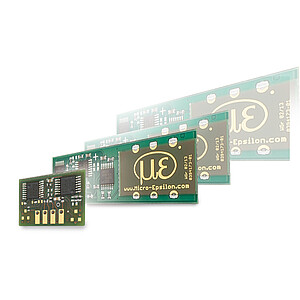

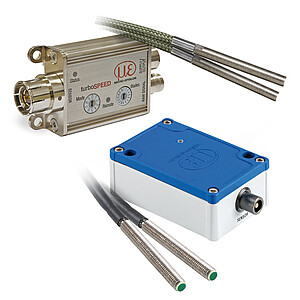

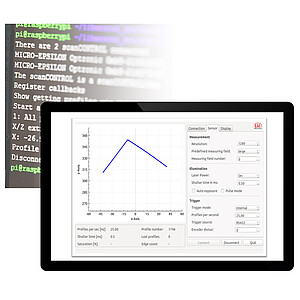

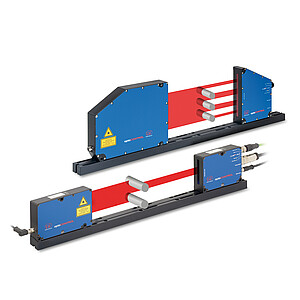

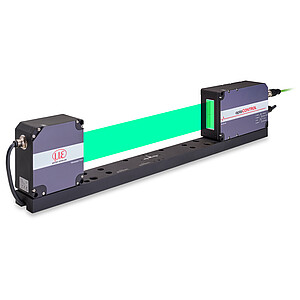

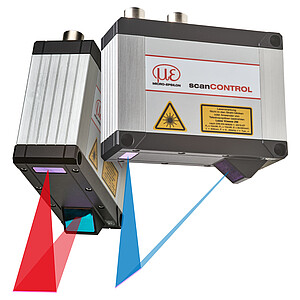

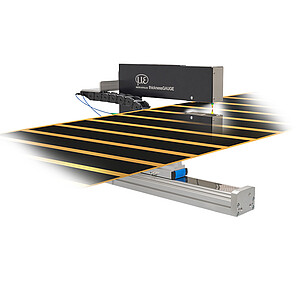

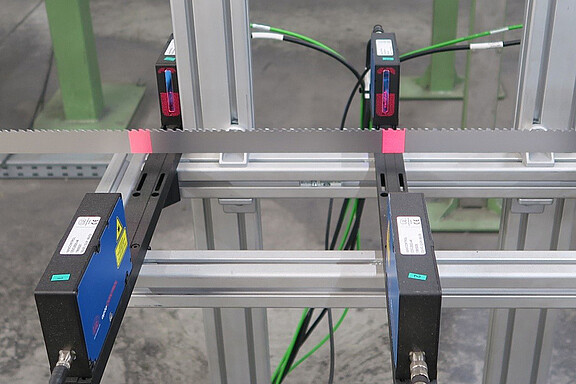

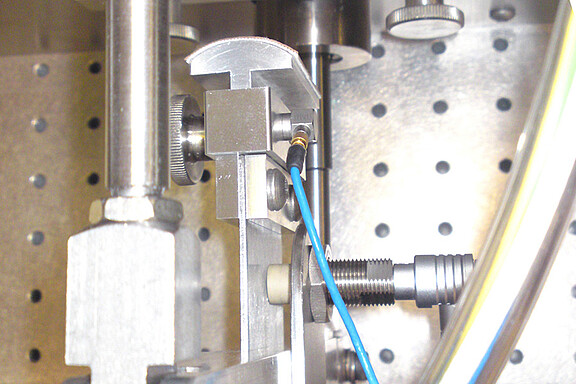

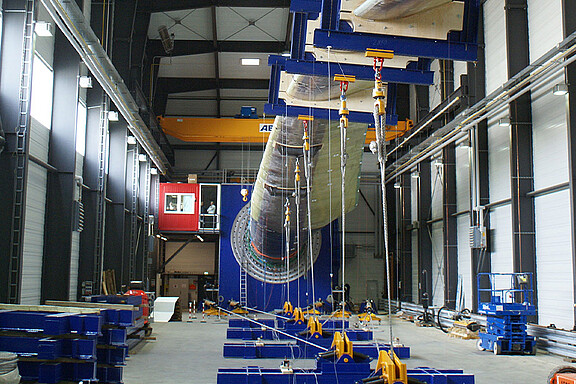

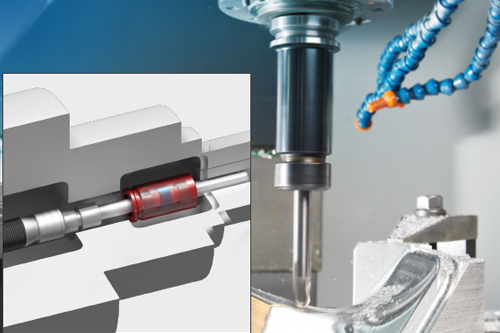

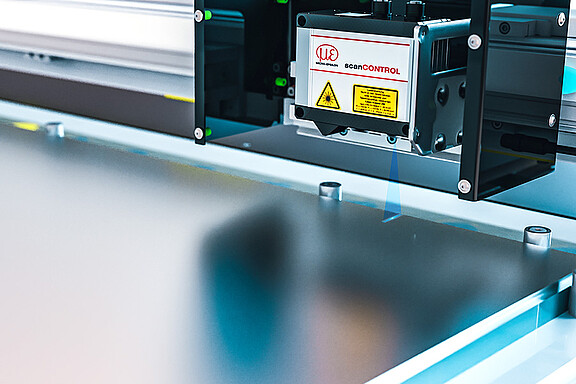

If objects are loaded with a weight or moved free-standing over a certain distance, a smaller or larger warping of the object always occurs. Measuring this deflection can be accomplished for larger objects using all possible distance sensors. On the other hand, if the deflection of a small slab should be measured, high precision measuring systems like those developed by Micro-Epsilon are necessary for this. Deflections from the metre range down to trillionths of a metre can be measured at Micro-Epsilon.