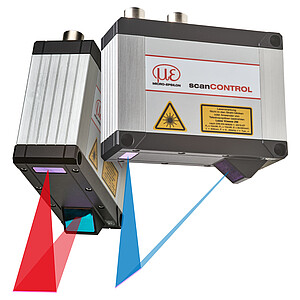

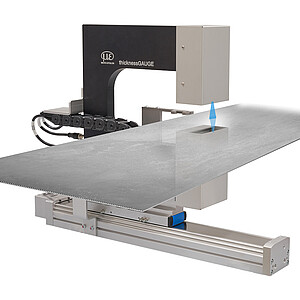

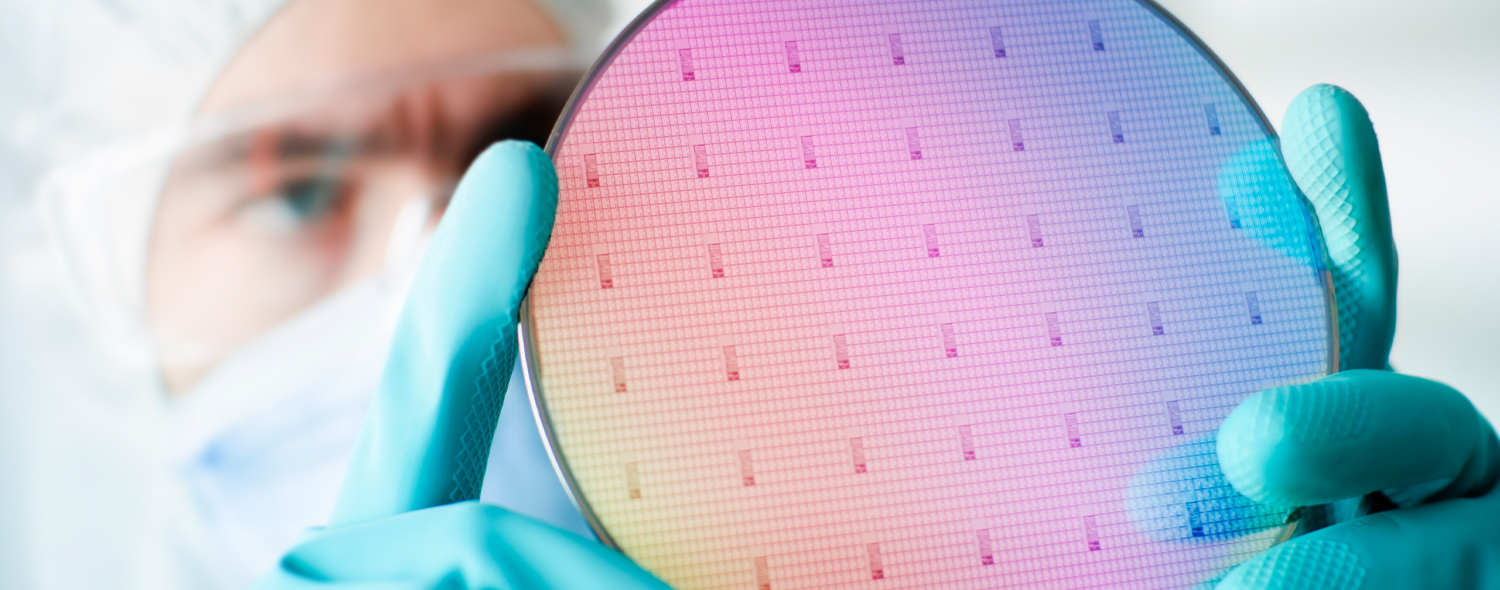

Highly precise sensor solutions for the semiconductor industry

Production lines in the semiconductor industry must be equipped with the latest sensors in order to meet increasingly stringent quality and cost requirements. This means accurately detecting the smallest of movements, reliably identifying when tolerances are exceeded even slightly, and monitoring processes that are at the limit of what is physically possible. Sensor technology by Micro-Epsilon has been used successfully in the semiconductor industry for many years, with the right solution for any measurement task: be it for complex front-end processes, back-end applications of wafer fab automation.

Why Micro-Epsilon?

- More precision and innovation – Made in Germany

- Consultation, development & production from a single source

- Hand in hand with our customers: quality and problem-solving expertise in series & OEM

- In-depth technological and practical knowledge in the field of semiconductor production

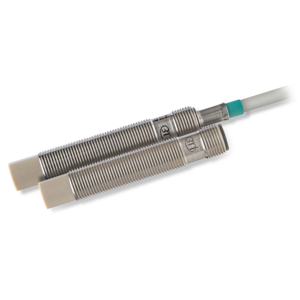

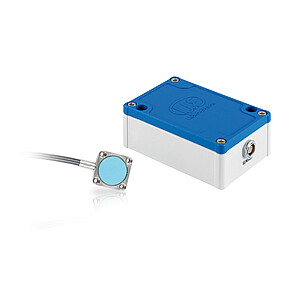

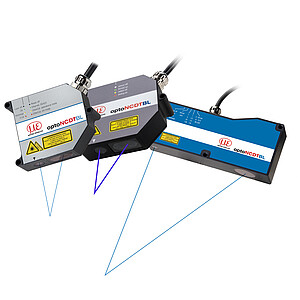

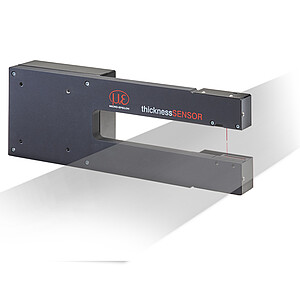

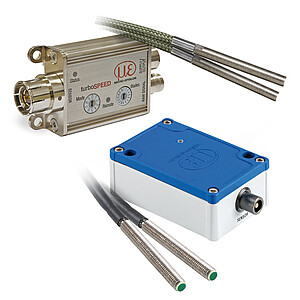

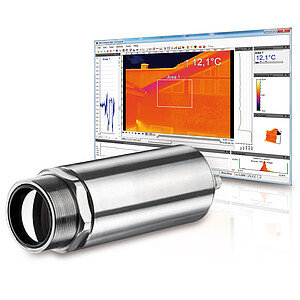

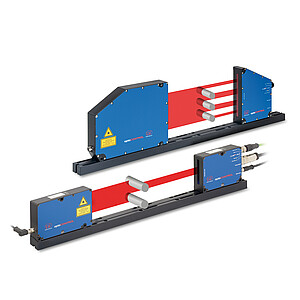

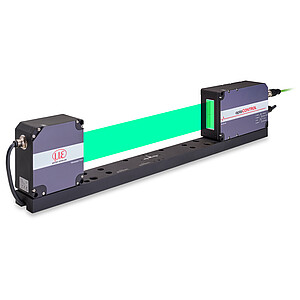

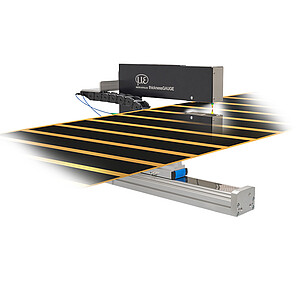

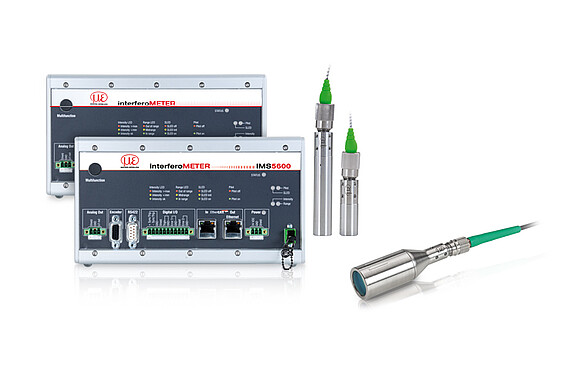

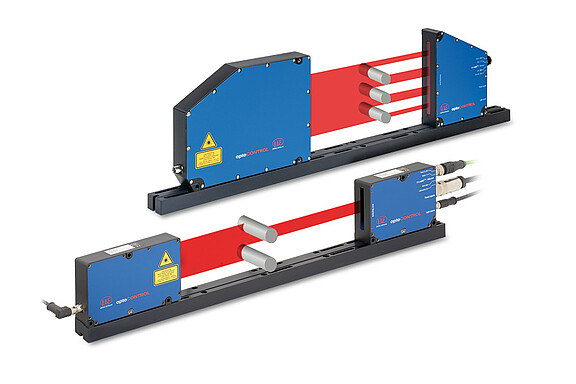

Precision sensors for dynamic machine monitoring and control

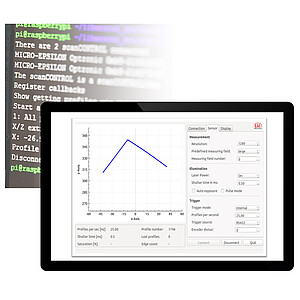

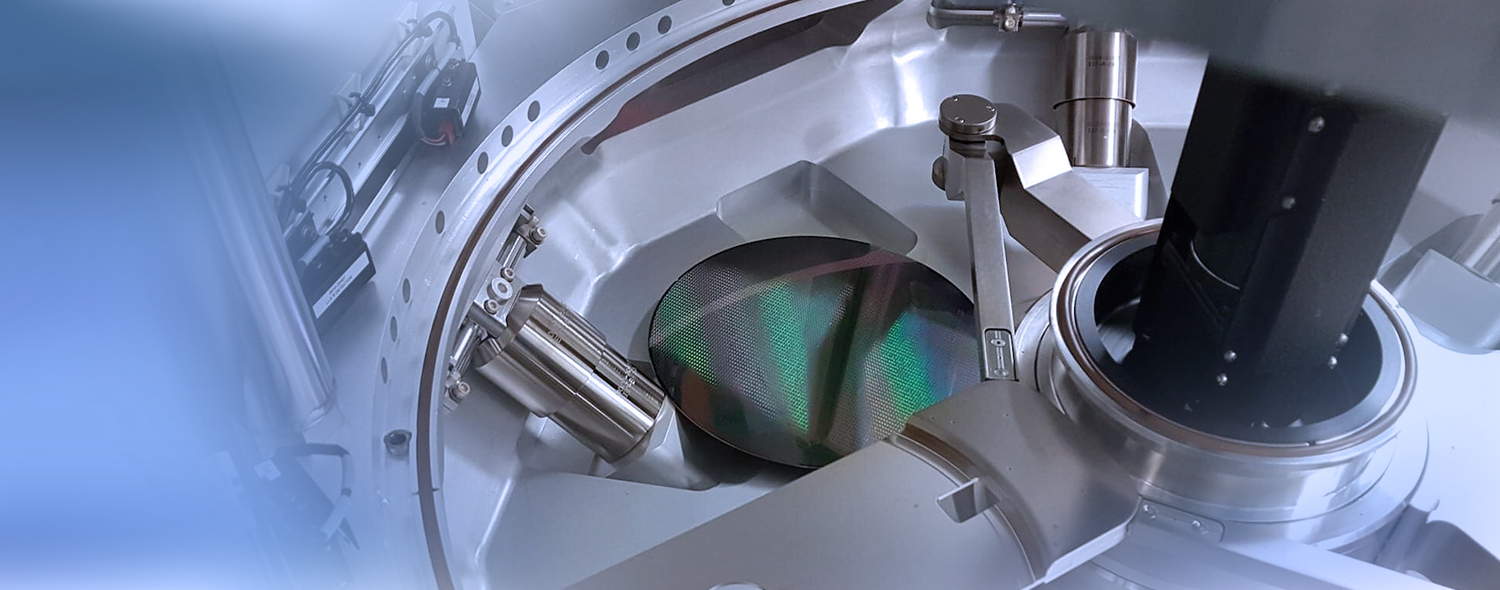

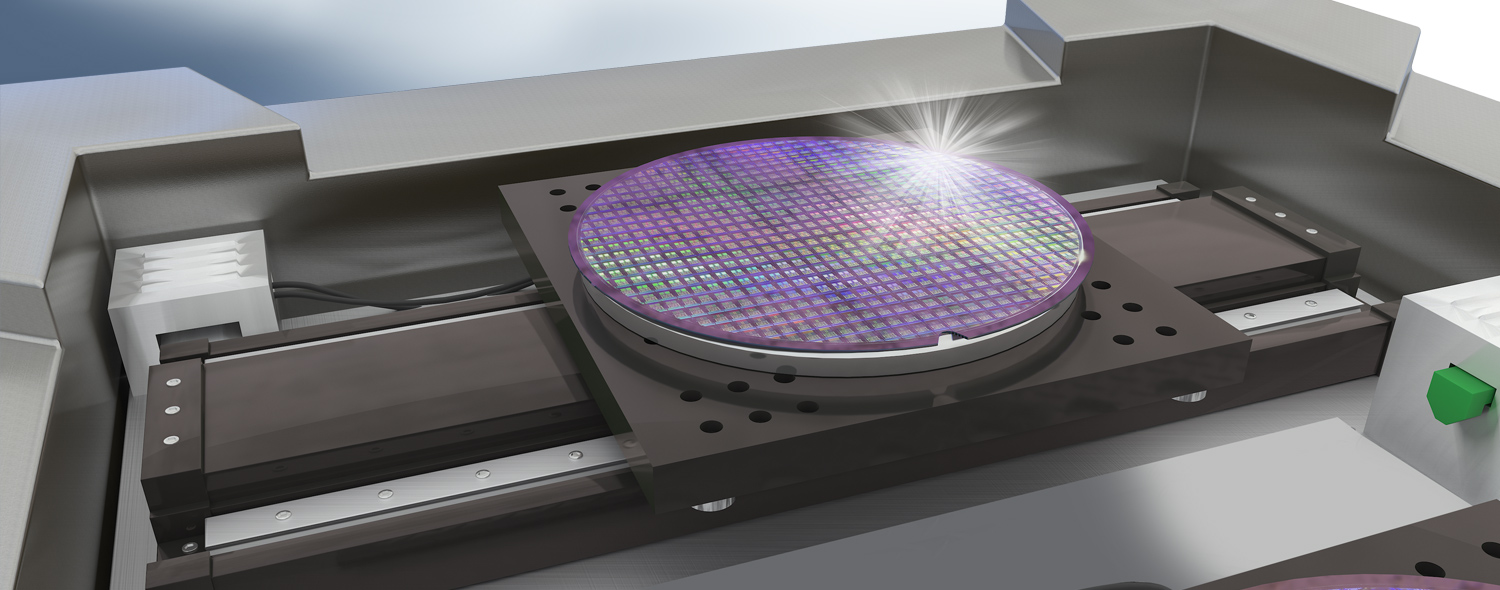

Optimized sensors from Micro-Epsilon deliver precise measurements in semiconductor engineering. They are used in applications with high acceleration, strong magnetic fields and ultra-high vacuums. The sensors are subject to the most rigorous of quality standards and monitor, among other things, the orientation of photomasks and lens systems, the positioning during wafer handling and the correct position of mirrors and optical elements.

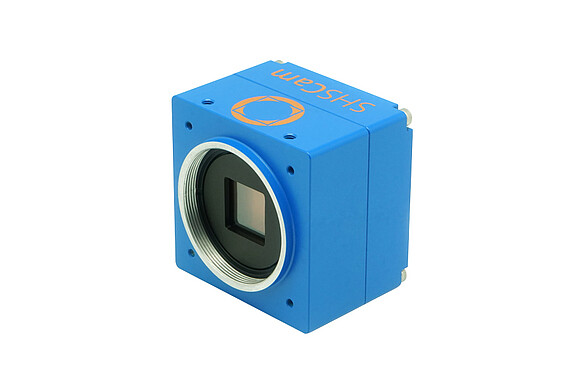

Our sensor solutions for the semiconductor industry

We offer a comprehensive range of precise sensors and measuring devices for a wide variety of process steps within semiconductor manufacture. We develop and produce adapted sensor and actuator solutions for series applications. We have the right manufacturing methods and capacities so that you can use the sensors even in challenging environments.

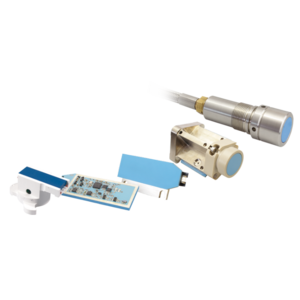

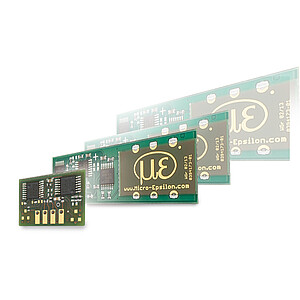

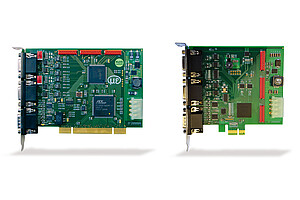

Modern manufacturing methods for highly precise displacement sensors

Due to the high demands in semiconductor manufacturing, all sensors and systems from Micro-Epsilon are put through rigorous manufacturing and testing processes. This relates, among other things, to the selection and placement of the electronics, the mechanical manufacturing procedure and special process technology. On top of that, application-specific sensor materials are used to meet the highest standards of quality.

- USP laser technology

- High-temperature vacuum soldering

- Precision manufacturing

- Burn-in tests

- Fully automated potting lines

- Passivation and coating of components and switch groups

More precision for semiconductors

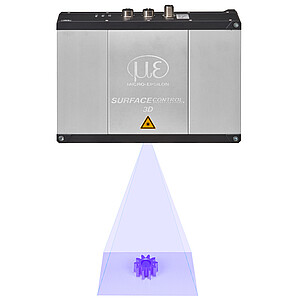

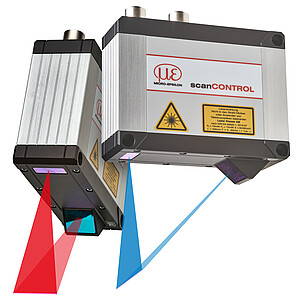

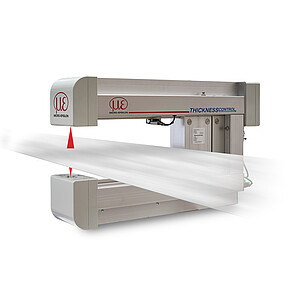

Micro-Epsilon offers the right solution for diverse applications in the semiconductor industry – from precise machine positioning to wafer inspection to topography measurements. The sensors are used in both front-end and back-end processes and stand out thanks to their supreme precision and reliability.

You can find application examples from the semiconductor industry here