3DInspect: Powerful software for all Micro-Epsilon 3D sensors

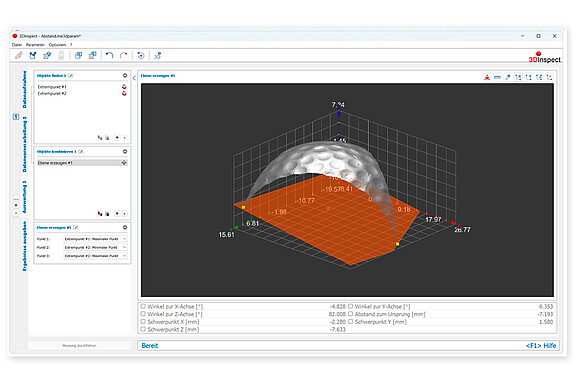

3DInspect is a uniform and user-friendly software tool for all 3D sensors from Micro-Epsilon. Parameter setting of the 3D sensors and recording of the measurement data are done directly in the 3DInspect software. Powerful tools allow point cloud alignment and filtering, intuitive detection and selection of relevant areas, and program combination. The 3D point clouds can be processed as required and measured values can be output to the controller.

The powerful software for all 2D/3D sensors. User-friendly. High-performing. Universal.

Characteristics

- One software for all Micro-Epsilon 3D sensors

- Highly compatible

- High flexibility for online and offline evaluation

- Simple operation via intuitive user interface

- Real 3D evaluation, not just 2.5D

- Object extraction in 3D

- Direct feedback for the algorithms

- Output directly to the controller (UDP, TCP, Modbus, Ethernet/IP, Profinet, EtherCAT)

- New: Surface inspection

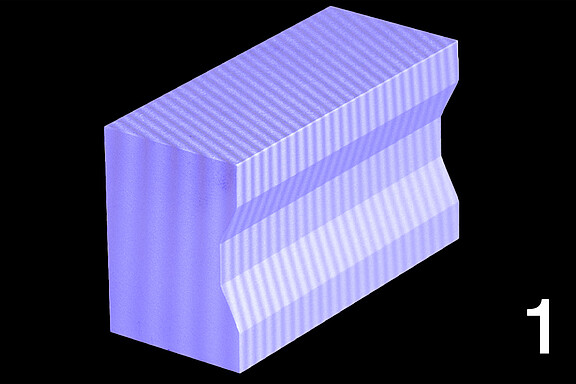

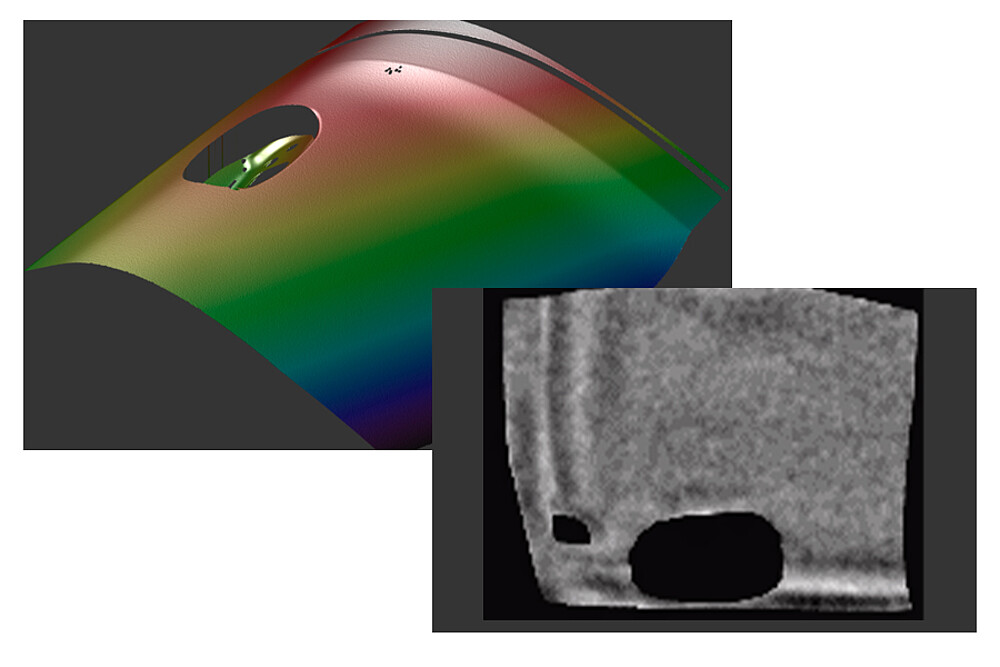

The unique Valid3D technology enables lossless display and processing of the point clouds. This is how scanned 3D objects can be moved arbitrarily in the coordinate system.

Advantages:

- Real 3D image of test object without data loss

- Analysis and evaluation of the complete test object

- Real 3D data instead of 2.5D evaluation

NEW: License extension - 3DInspect 3.0 for surface inspection

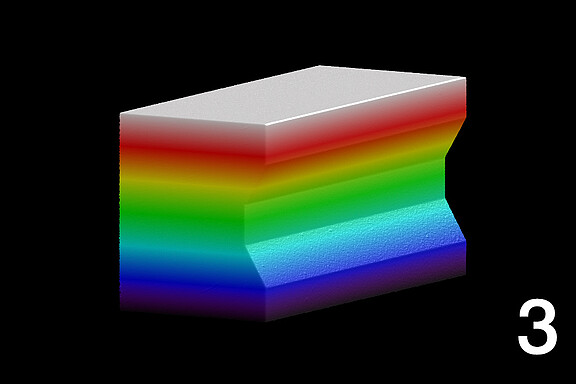

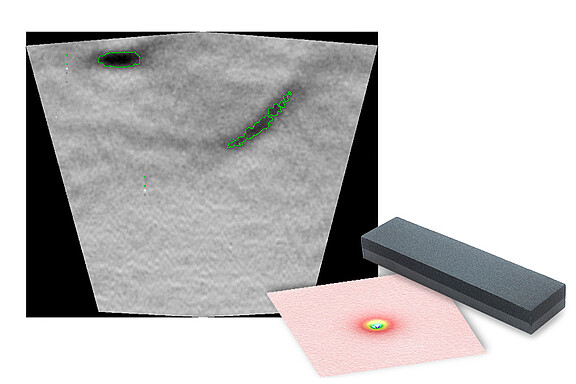

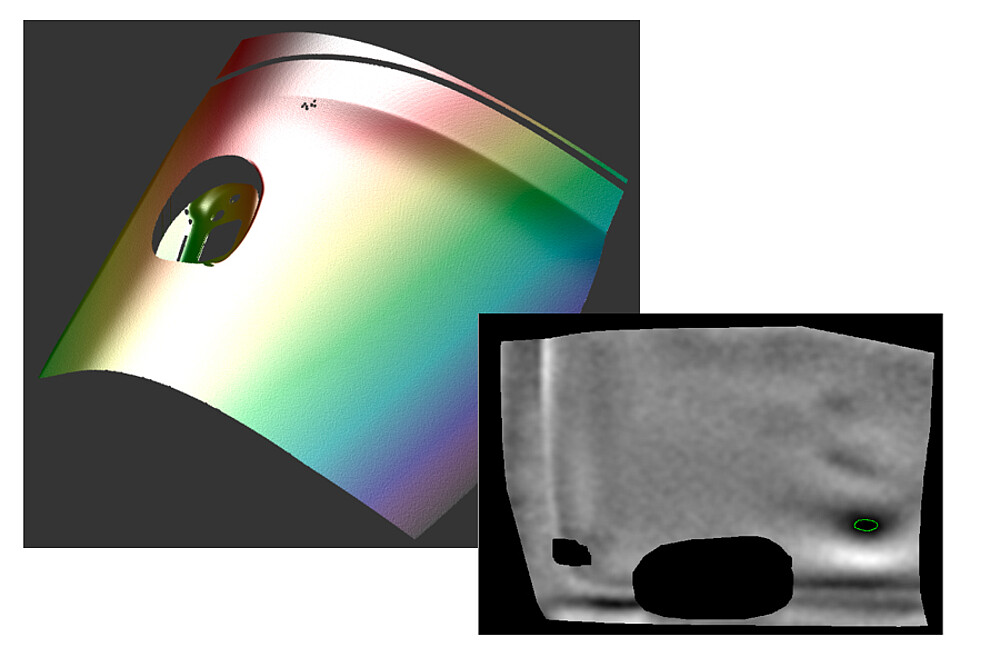

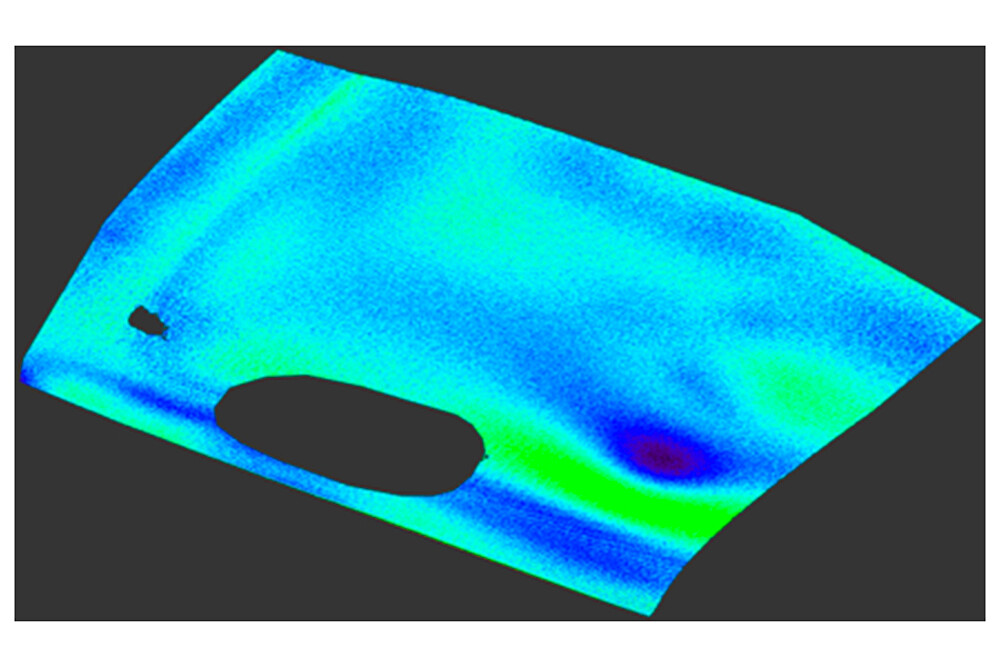

The functional extension for surface inspection can detect deviations from a homogeneous surface. This means that 3DInspect 3.0 can be used for digital quality control. The test is performed according to predefined criteria, eliminating subjective influences. This allows for defects to be detected at an early stage.

Major new features:

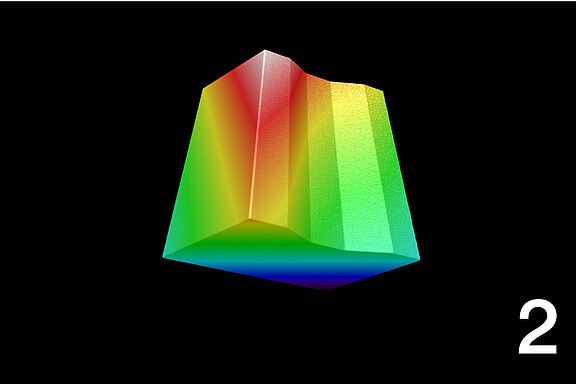

- Digital Stone simulates a physical whetstone. High precision with high repeatability

- Digital Master: Objective target/actual comparison with good parts (incl. considered variance)

- Defect detection with sorting and counting function: automatic defect detection and height evaluation

Component testing at a new level - thanks to the Digital Master

Teaching a digital master enables a target/actual comparison. This means that several IO parts are merged into a master file. The components to be tested can then be compared with this master file and analyzed.

| 3DInspect | Basic software for free download |

Functional extension "Automation" |

Functional extension "Surface inspection" |

|---|---|---|---|

| Sensor parameterization | ✓ | ✓ | ✓ |

| Display 3D point cloud | ✓ | ✓ | ✓ |

| Evaluation of 3D data | ✓ | ✓ | ✓ |

| Controlling the software via the PLC | ✓ | ||

| Sending measurement results to the controller / software | ✓ | ||

| Logging data | ✓ | ||

|

Pre-processing defect detection |

✓ |

Powerful programs for 3D evaluation

3DInspect transmits the measurement data from the sensor via Ethernet to a PC and provides the data in three-dimensional form. For further processing, evaluation and assessment, the software has powerful measurement programs. The pre-configured measuring programs are divided into the categories "Data preprocessing", "Find objects" as well as in "Combine objects" and allow various setting options, e.g.:

- Simple alignment of the point cloud

- Filtering of the entire point cloud for smoothing and optimization

- Trend removal, Digital Stone and Digital Master for surface inspection

- Simple selection of the Region of Interest, e.g. edge, center, maximum point, pad

- Calculation programs for distances, heights, angles, radii

- Defect detection with sorting and counting function

- Signal output OK/nOK