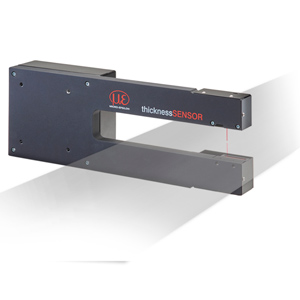

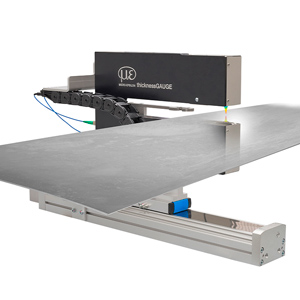

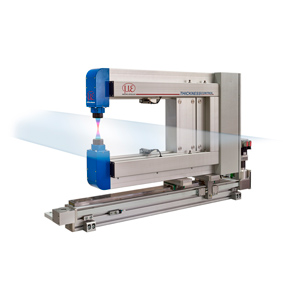

White light interferometer for high precision wafer measurement

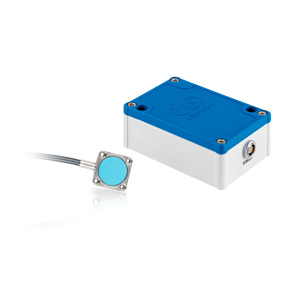

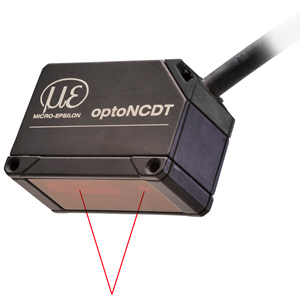

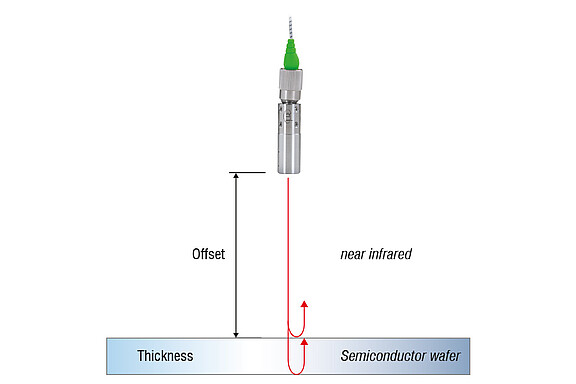

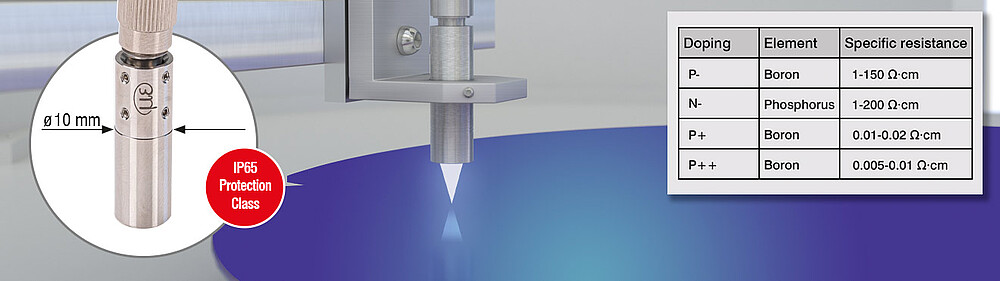

The IMS5420 is a high-performance white light interferometer for non-contact thickness measurement of monocrystalline silicon wafers. The controller has a broadband superluminescent diode (SLED) with a wavelength range of 1,100 nm. This enables the thickness measurement of undoped, doped and highly doped SI wafers with only one measuring system. The IMS5420 achieves a signal stability of less than 1 nm. The thickness can be measured from a distance of 24 mm.

Characteristics

- Nanometer-accurate thickness measurement of undoped, doped and highly doped wafers

- Multi-peak: acquisition of up to 5 layers with an SI thickness of 0.05 up to 1.05 mm

- High resolution in z-axis of 1 nm

- Measuring rate up to 6 kHz for fast measurements

- Ethernet / EtherCAT / RS422 / PROFINET / EtherNet/IP

- Easy parameterization via web interface

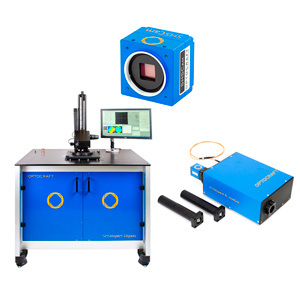

Precise wafer thickness measurement

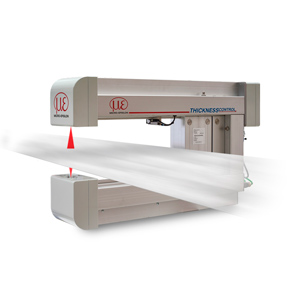

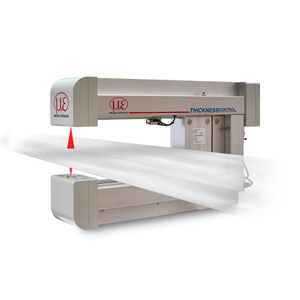

Due to the optical transparency of silicon wafers in the wavelength range of 1,100 nm, the IMS5420 interferometers can precisely detect the thickness. In this wavelength range, both undoped silicon and doped wafers provide sufficient transparency. Therefore, wafer thicknesses up to 1.05 mm can be detected. The measurable thickness of the air gap is even up to 4 mm.

The IMS5420 interferometer enables the thickness measurement of undoped, doped and highly doped silicon wafers and thus offers a wide range of applications. This wafer thickness measuring system is ideal for the measurement of monocrystalline silicon wafers with a geometric thickness of 500 to 1050 µm and a doping of up to 6 m Ω cm. Even with highly doped wafers, thicknesses up to 0.8 mm can be measured. This results from the decreasing transparency with increasing doping.

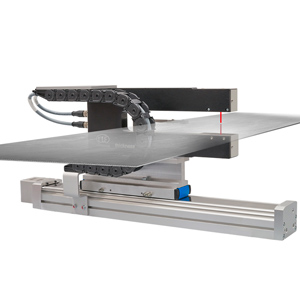

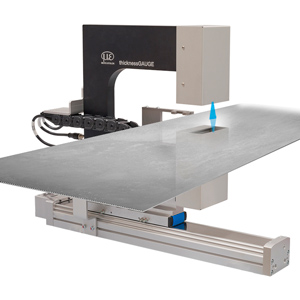

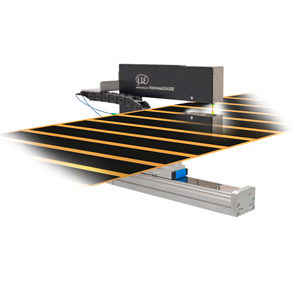

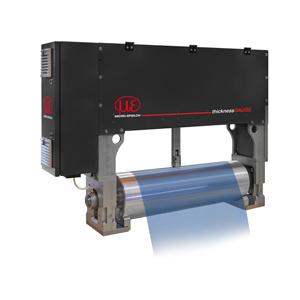

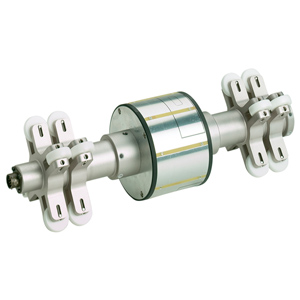

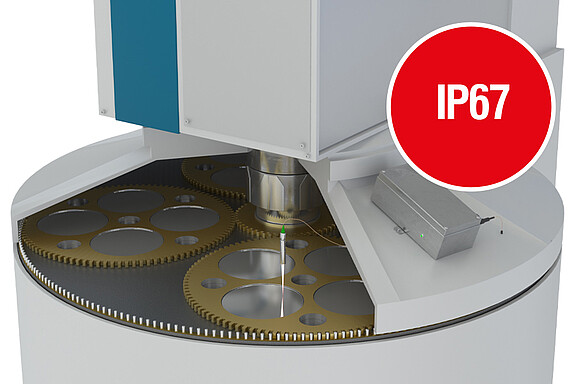

Precise thickness measurement during lapping

In wafer fabrication, a crystalline silicon ingot is cut into thin slices of about 1 mm. The discs are then ground and lapped to obtain the desired thickness and surface finish. To achieve high process stability, interferoMETERs are used for inline thickness measurement in lapping and grinding machines. Due to its compact design, the sensor can also be integrated in confined installation spaces. The thickness values are used for machine control as well as for quality control of the wafer.

| Model | Measuring range / Start of measuring range |

Linearity | Number of measurable layers | Fields of application |

|---|---|---|---|---|

| IMS5420-TH24 | 0.05 ... 1.05 mm (for silicon, n=3.82) 0.2 ... 4 mm (for air, n=1) / approx. 24 mm with a working range of approx. 6 mm |

< ±100 nm | 1 layer | Inline thickness measurement, e.g. after grinding or polishing. |

| IMS5420MP-TH24 | < ±100 nm for one layer < ±200 nm for additional layers |

up to 5 layers | Inline thickness measurement, e.g. for quality control of the coating thickness after coating | |

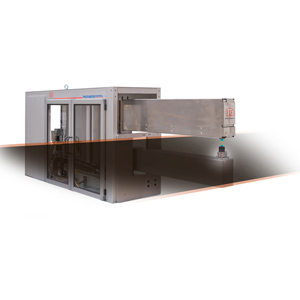

| IMS5420/IP67-TH24 | < ±100 nm | 1 layer | Industrial inline thickness measurement during lapping and grinding |

Modern interfaces for integration into machines and systems

The controller offers integrated interfaces such as Ethernet, EtherCAT and RS422 as well as additional encoder connections, analog outputs, synchronization inputs and digital I/Os. When you use Micro-Epsilon's interface modules, PROFINET and EthernetIP are available. This allows the interferometer to be integrated into all control systems and production programs.