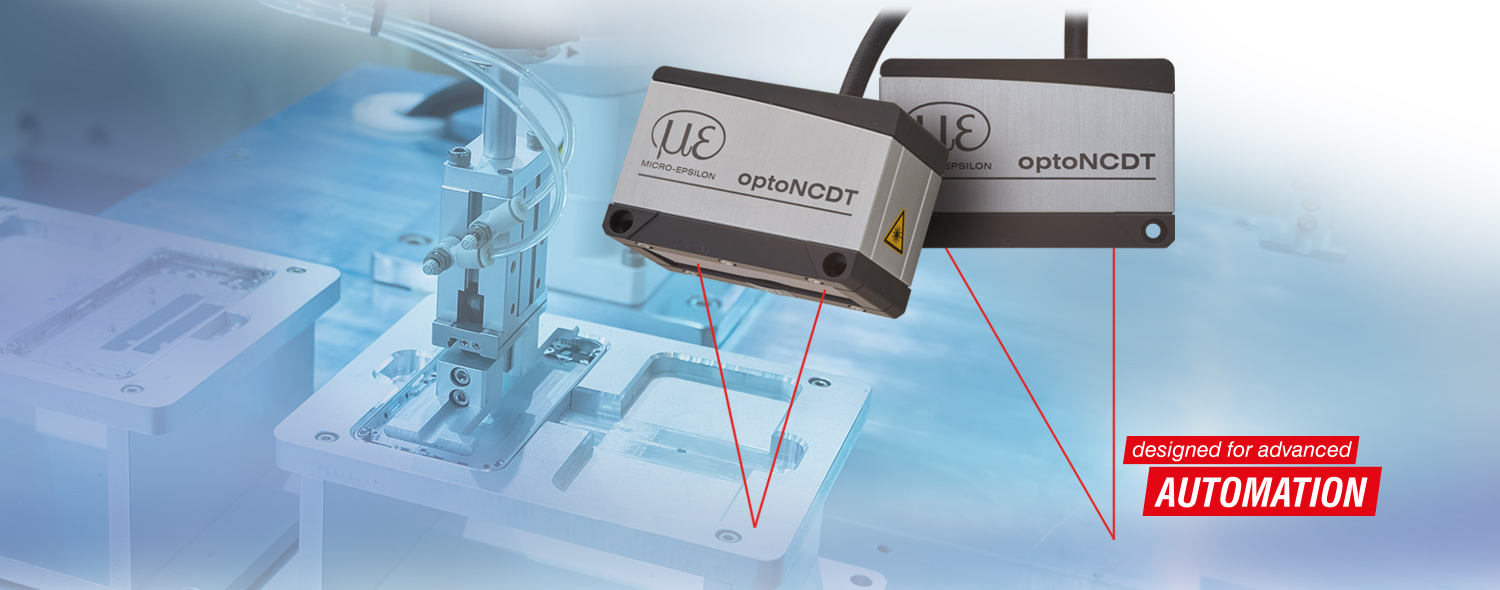

Laser displacement sensors for Advanced Automation

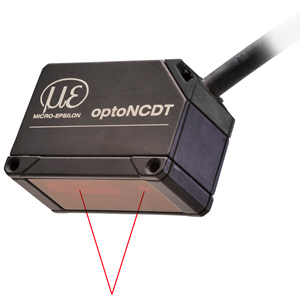

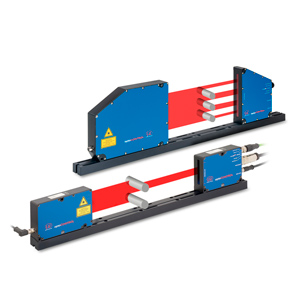

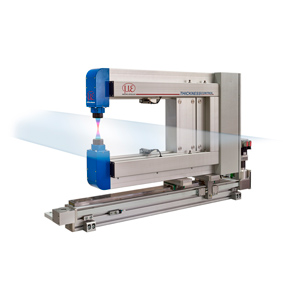

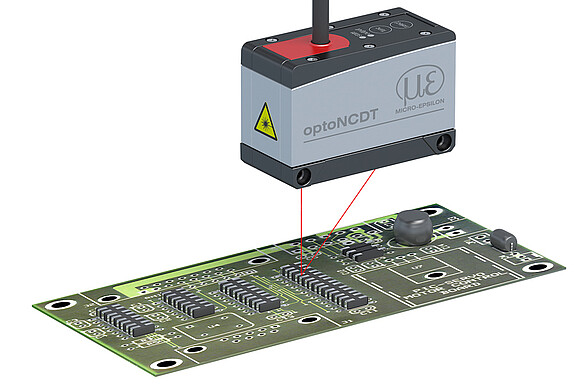

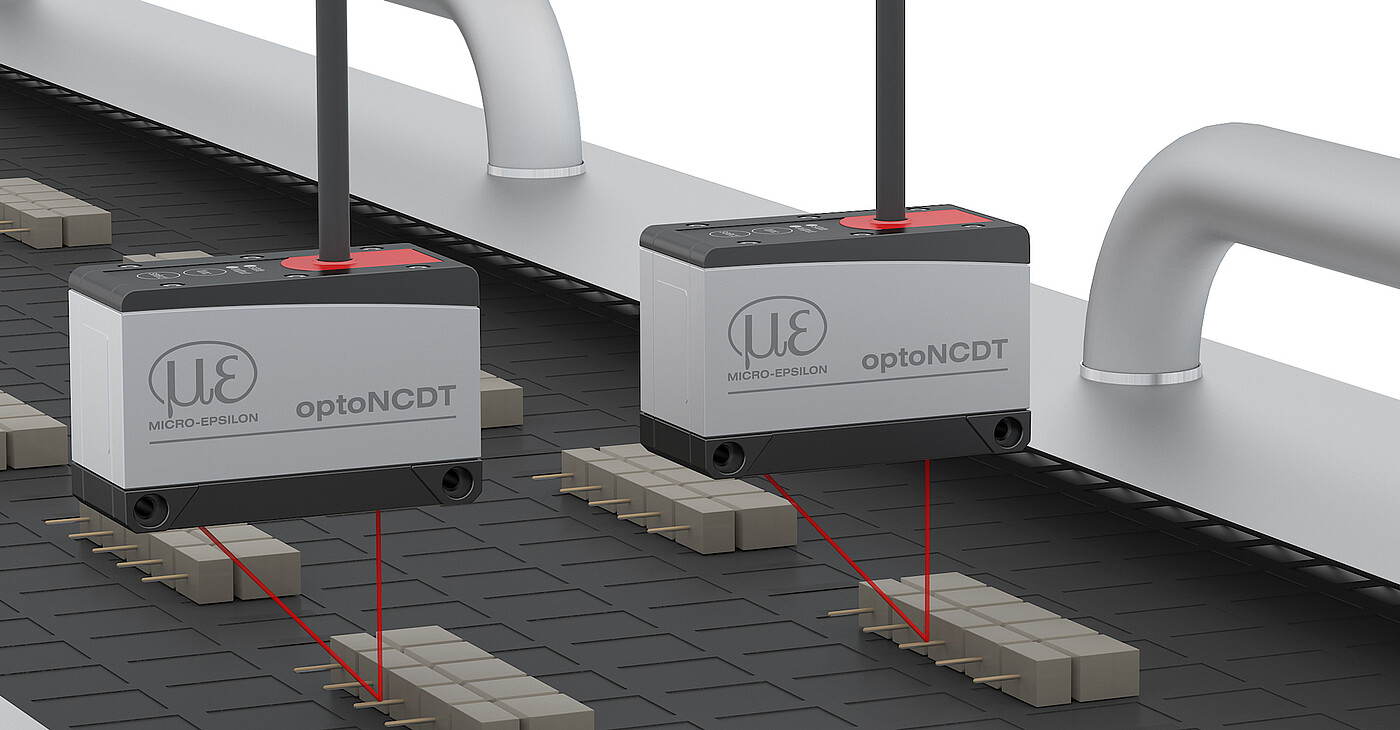

The optoNCDT 1900 offers a unique combination of speed, size, performance and application versatility for displacement, distance and position measurements. This compact triangulation sensor achieves a high measurement accuracy and measuring rates of up to 10 kHz. The high-performance optical system generates a small light spot which enables to even detect the finest of details and structures reliably.

Characteristics

- Measuring ranges (mm): 2 | 6 | 10 | 25 | 50 | 100 | 200 | 500

- Linearity from 1 µm

- Adjustable measuring rate up to 10 kHz

- Analog and digital outputs

- Compact size with integrated electronics

- Advanced Surface Compensation for fast adaption to changing surfaces

- Predefined and individual presets in the web interface

- Integrated EtherCAT, EtherNet/IP and PROFINET interface

- Certified according to UL 61010-1

Laser sensors for industrial series applications

The optoNCDT 1900 is used for dynamic displacement, distance and position measurements and impresses with its speed, design and accuracy. The integrated high-performance controller enables fast and highly precise processing and output of measurement values.

The innovative optoNCDT 1900 laser triangulation sensor is used whenever maximum precision is combined with the latest technology, e.g., in Advanced Automation, the automotive industry, 3D printing and coordinate measuring machines.

Individual configuration of series applications

For such series applications, we configure our sensors to individual requirements. Alternative cable lengths, connector types and firmware options can be implemented. Feel free to contact us, we will be happy to advise you!

Now with integrated Industrial Ethernet interface

The latest optoNCDT 1900 laser triangulation sensors are also available with integrated Industrial Ethernet interface. Depending on the model, you can integrate the full sensor performance into your PLC directly via EtherCAT, EtherNet/IP or PROFINET without any additional interface module. You benefit from real-time data without time delay as well as reduced installation and wiring effort. The sensor parameters can be set directly via Industrial Ethernet or still via web interface. For high speed measurements, the sensor offers an Oversampling feature which allows measurement data to be detected or transmitted four times faster than the PLC's polling cycle.

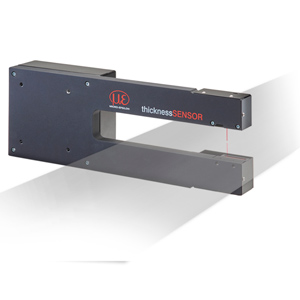

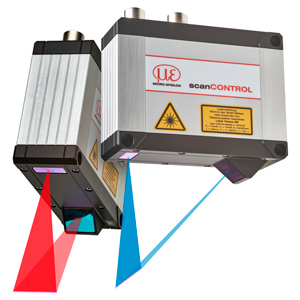

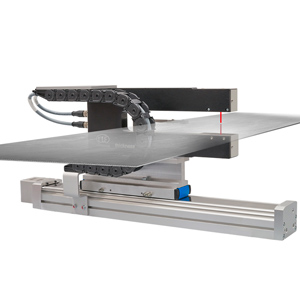

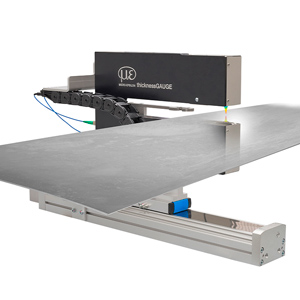

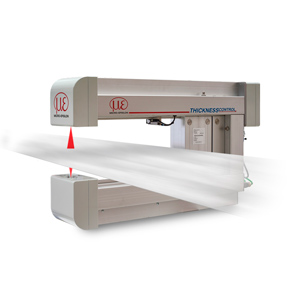

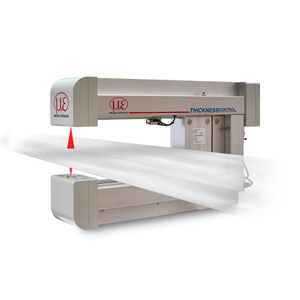

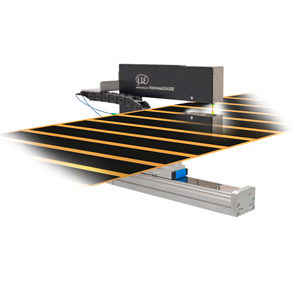

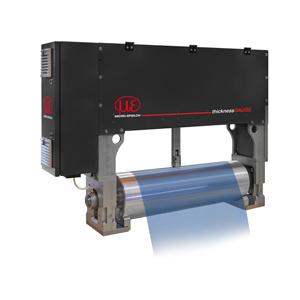

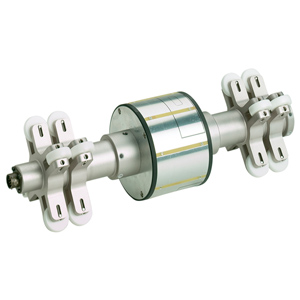

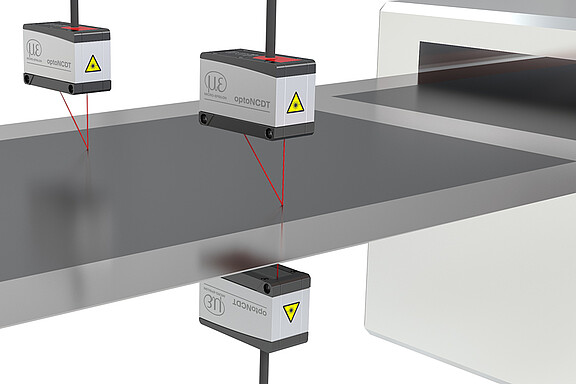

Optimized for thickness measurements of electrode coating

The optoNCDT 1900 laser sensors are now also available with a measuring range of 6 mm. Its laser-line beam design makes this sensor ideally suitable for inline thickness measurements in battery cell production. The electrode coating is a dried paste (the so-called slurry), which is applied on both sides of an aluminum film (for the cathode) or on a copper film (for the anode). Subsequent drying and calendering forms a partially very porous surface. Specially designed for measurements on rough surfaces, the small laser line is ideal for this application since it compensates for surface irregularities. The thickness values of the coated film obtained in this way are used for quality assurance.

Both its high accuracy and its very compact size make the optoNCDT 1900 ideally suitable for this type of measurement tasks.

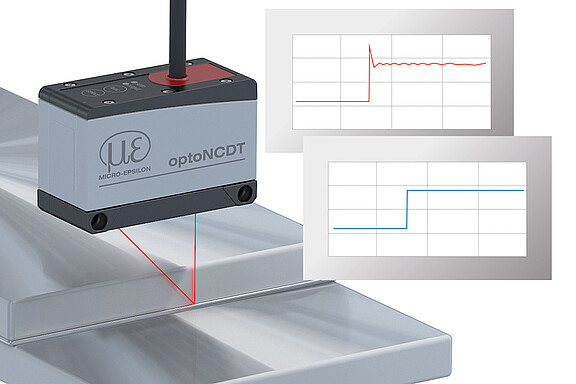

Highest stability based on intelligent signal optimization

For the first time, a two-step measurement value averaging is available to optimize the signal. This enables a smooth signal at edges and steps. Especially for high speed measurements of moving parts, the high-performance averaging enables a precise signal course.

Advanced Surface Compensation - The intelligent exposure control for demanding surfaces

The optoNCDT 1900 is equipped with an intelligent surface control feature. New algorithms enable stable measurement results even on demanding surfaces presenting changing reflections. In addition, the sensor is extremely resistant to ambient light and can also be used in strongly illuminated environments. New algorithms compensate for ambient light up to 50,000 lux.

Simple installation and initial operation

Mounting the sensor using fitting sleeves automatically aligns the sensor in the correct position. This enables both easy sensor replacement and even higher precision in solving measurement tasks. Thanks to its small dimensions, the laser sensor can also be integrated in confined spaces.

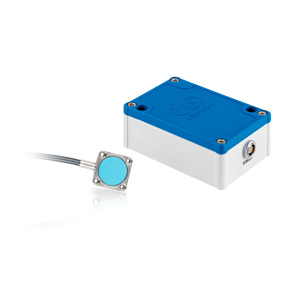

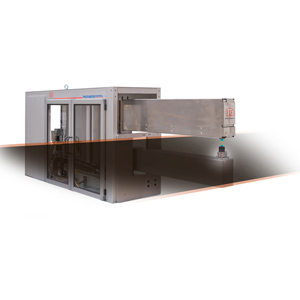

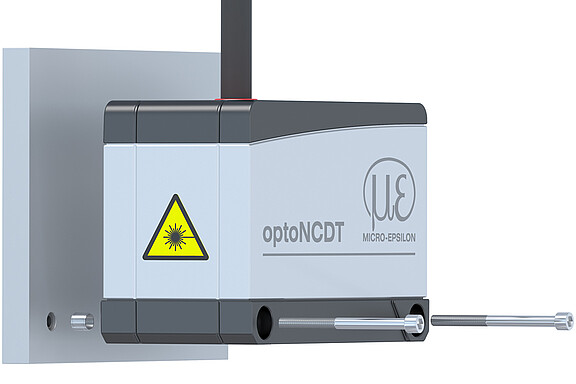

Protective housing with air purge and cooling

A compact protective housing is available for the optoNCDT 1900 laser sensors, which can be easily attached. The protective housing has an air purge for cleaning the protective windows. The air purge simultaneously cools the sensor. The protective housing does not completely enclose the sensor, as the sensor itself has IP67 protection.

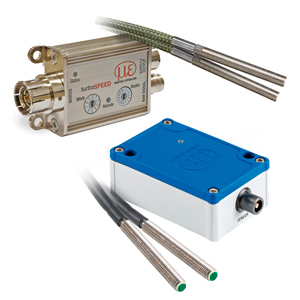

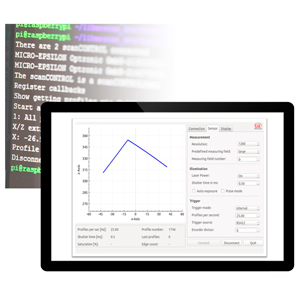

Interface and signal processing units

Modern interfaces for integration into machines and systems

The laser sensor is equipped with an RS422 interface and analog outputs. The Micro-Epsilon interface modules also offer EtherNet/IP and PROFINET.