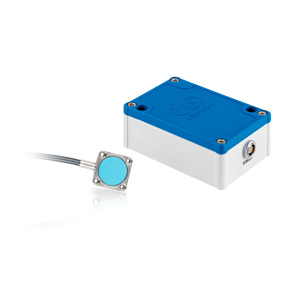

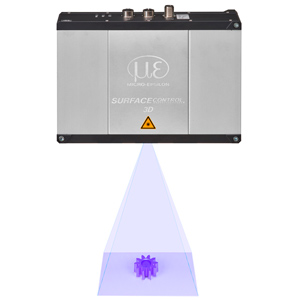

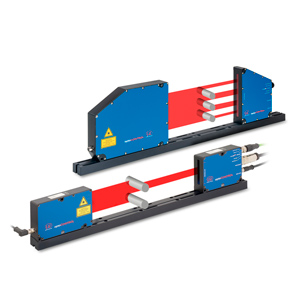

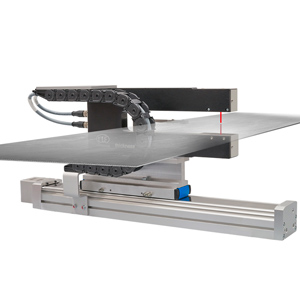

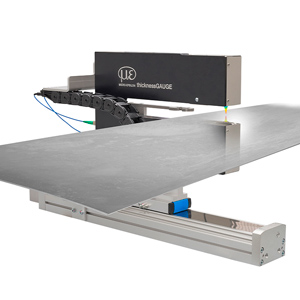

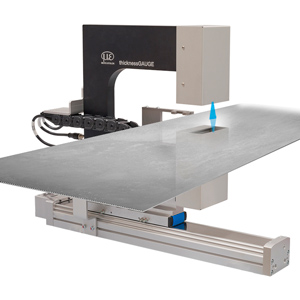

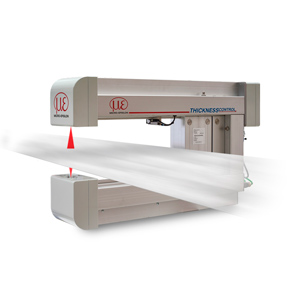

Optical precision micrometer with high resolution

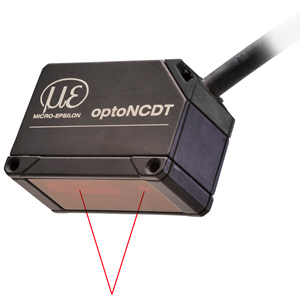

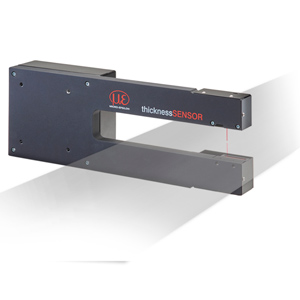

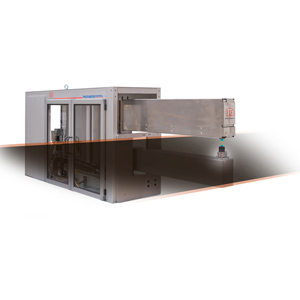

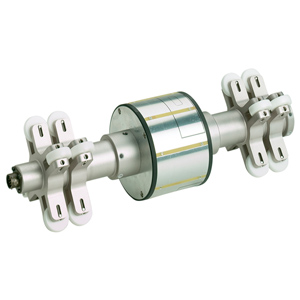

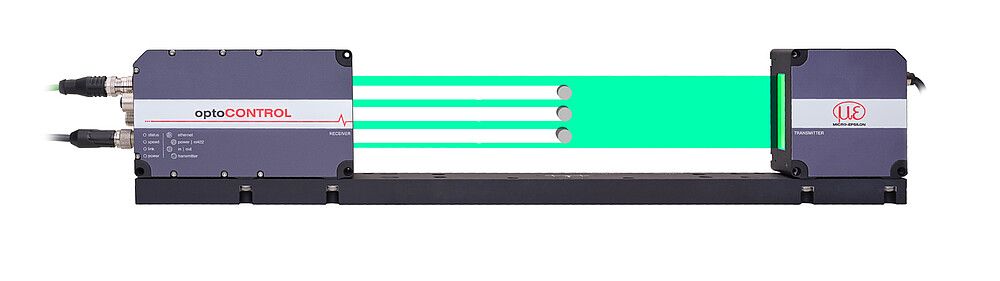

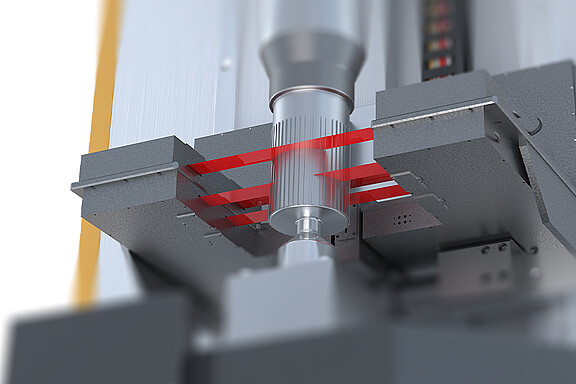

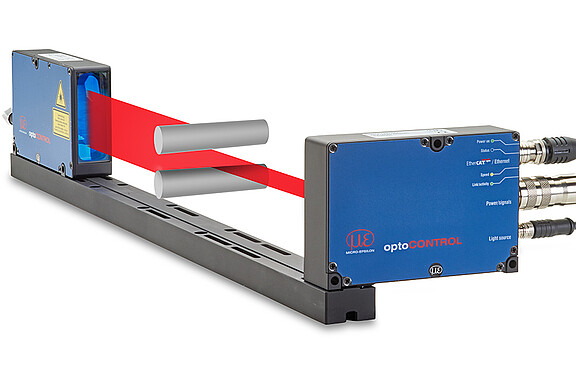

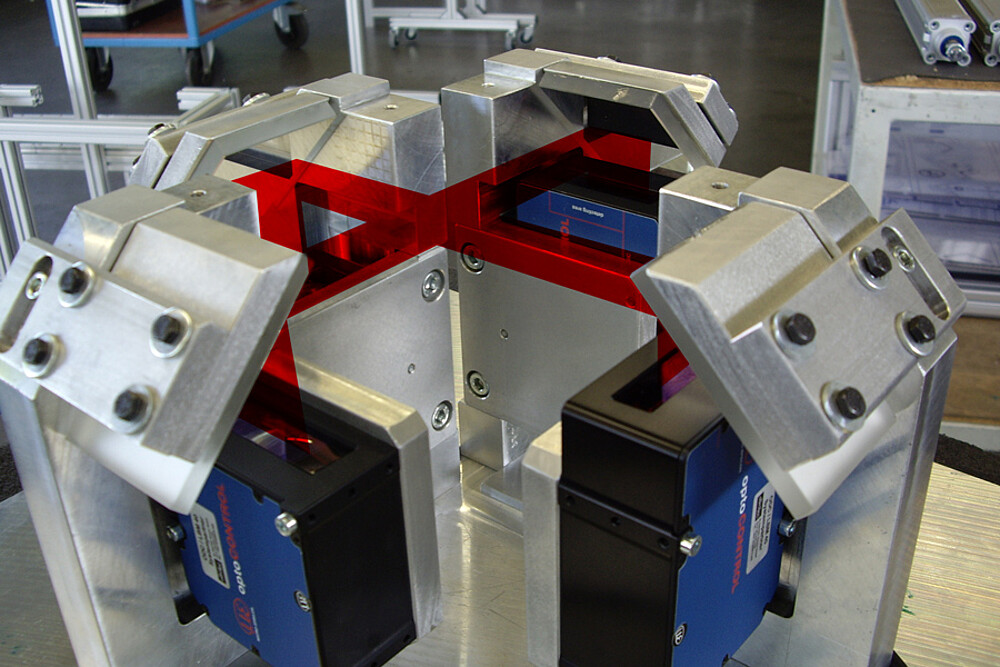

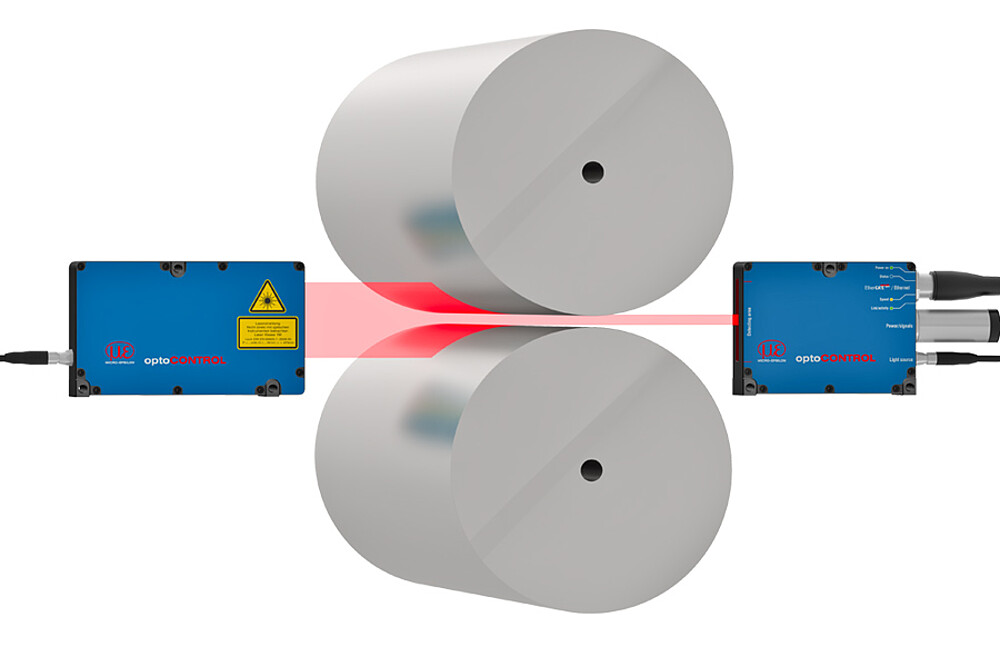

Optical micrometers from Micro-Epsilon operate according to the transmitted light principle (ThruBeam micrometer). Here, the transmitter produces a parallel light curtain that is transmitted via a lens arrangement into the receiver unit. The beam is interrupted if an object is in the light path. The resulting shadowing is detected by the receiving optics and output as measurement value. Most optical micrometers are used for dimensional measurements in production, machine monitoring and quality assurance. Parameters such as diameter, gap, height and position are detected with high accuracy.

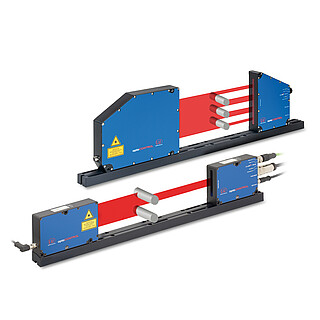

Models

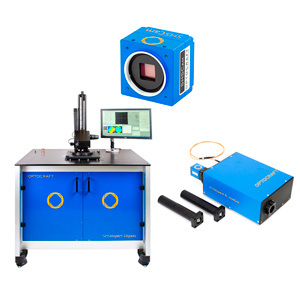

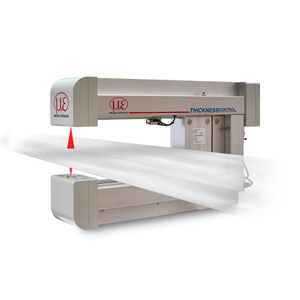

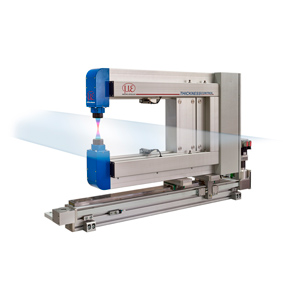

New: High performance micrometer for highest requirements

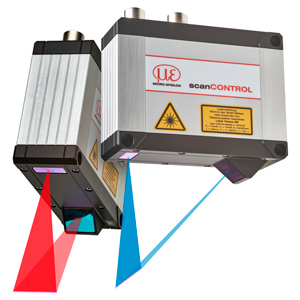

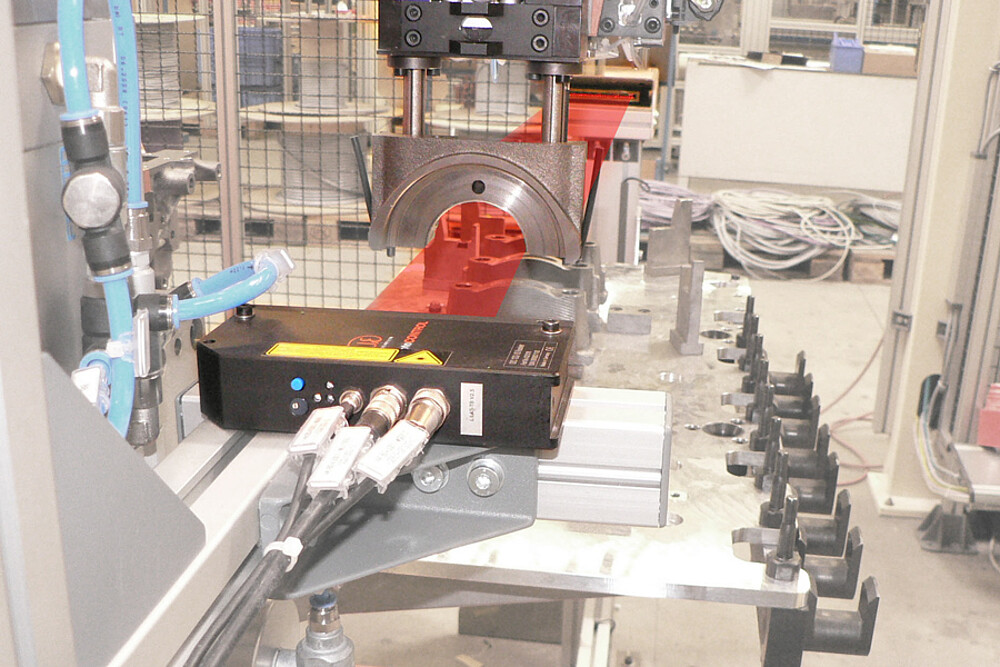

The optoCONTROL 2700 is a compact LED micrometer for the precise measurement of diameter, gap, edge and segment. It impresses with high accuracy, comprehensive measuring programs and innovative evaluations for automation technology and machine building.

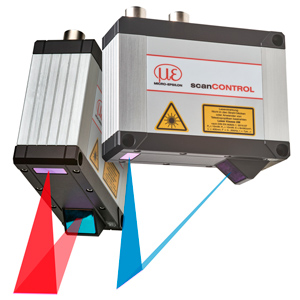

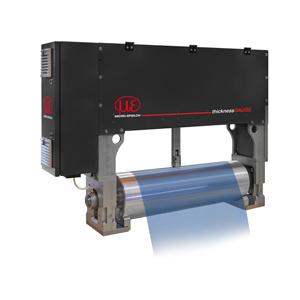

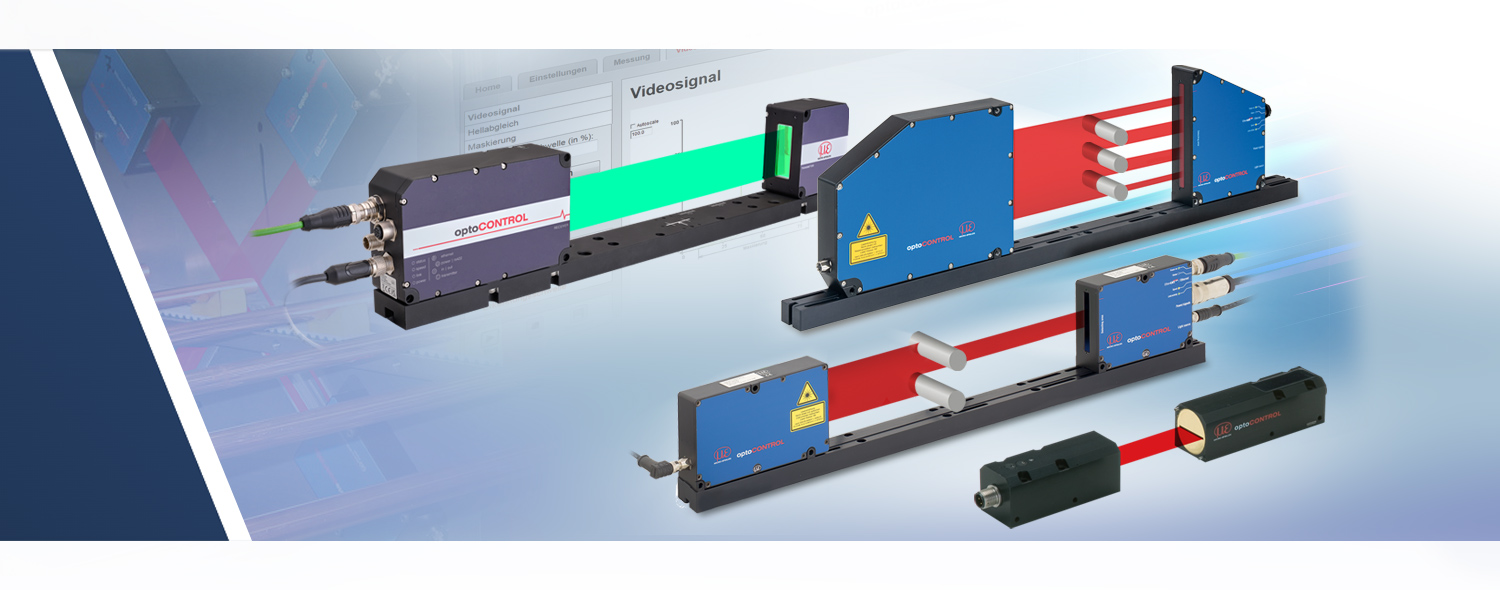

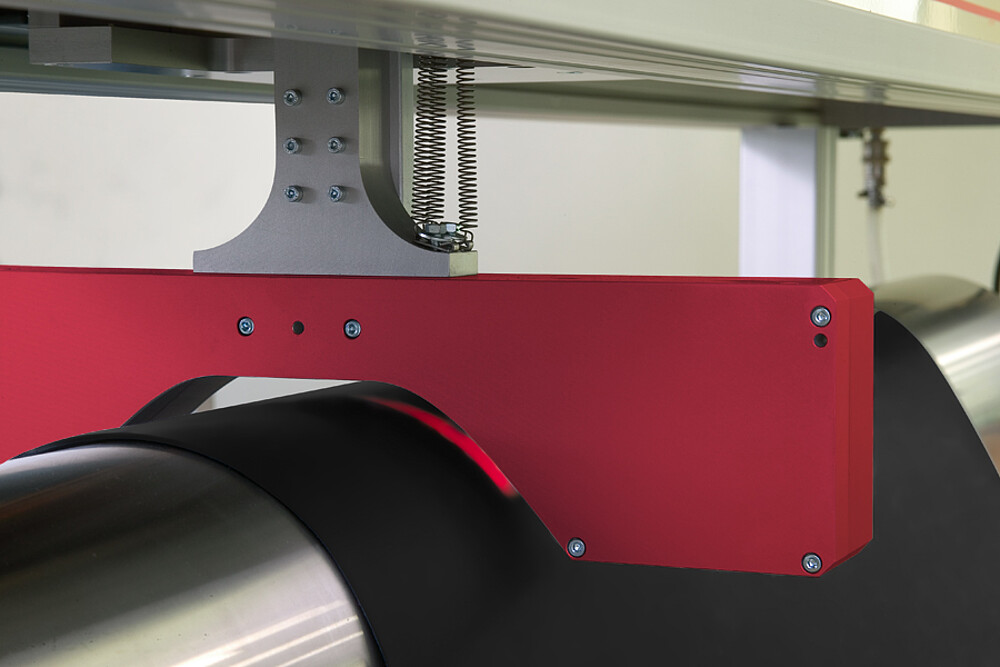

Wear-free and durable design for reliable measurements

All optoCONTROL laser micrometers operate without rotating mirrors and are therefore completely wear-free. The parallel light curtain is created by special optics in the light source. High quality components in the receiving optics, e.g. filters and lenses, enable the high accuracy of the micrometers. This is why optoCONTROL micrometers are particularly suitable for areas where high precision and reliability are required.

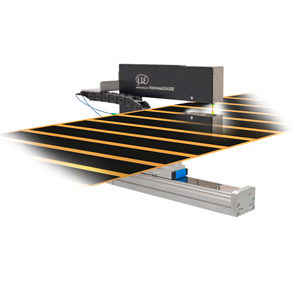

Versatile in application

Laser micrometers are primarily used as part of the manufacturing process and quality monitoring in the production line, measuring continuous material, as well as single parts. The compact models of the optoCONTROL family are suitable for applications in production lines, as well as for integration in machines and automated production systems. The high measuring rates ensure a high and continuous cycle rate in the production process.