Measuring and inspection systems for the metal processing industry

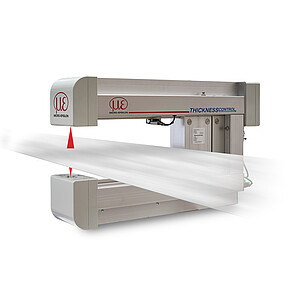

For the steel and aluminum industry, Micro-Epsilon offers innovative measuring and inspection systems for thickness, profile and surface measurements. Performance and quality, as well as reliability of products and services have made Micro-Epsilon one of the leading suppliers of inspection systems for optical thickness measurement used in the metals industry.

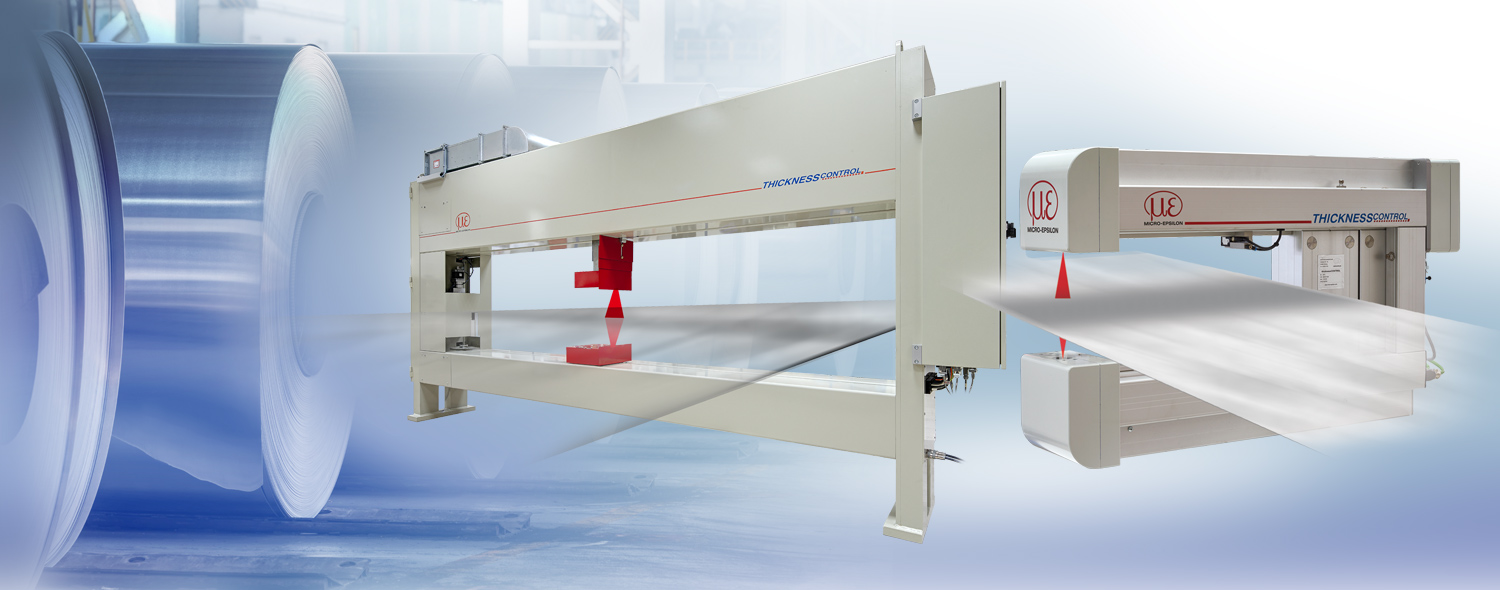

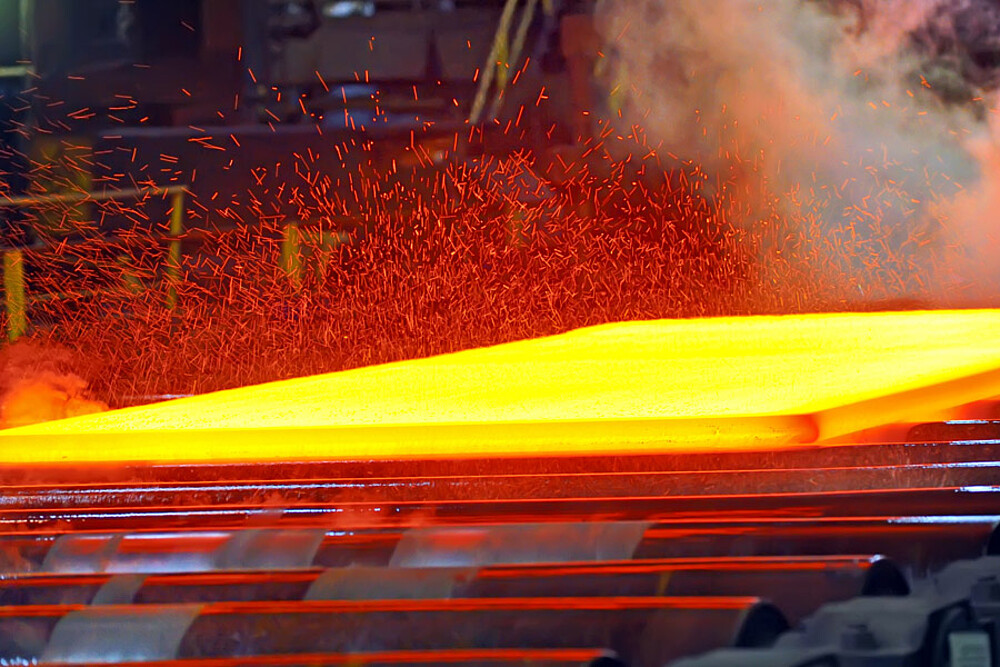

Our non-contact thickness measuring systems are used wherever high-precision thickness monitoring is required for control and quality assurance. Both in hot rolling mills, in continuous casting plants and in cold rolling mills and service centers, the Micro-Epsilon measuring systems operate reliably and with maximum precision. Numerous, successful installations in 13 countries around the world in milling lines and processing lines speak for themselves.

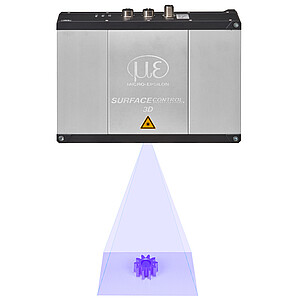

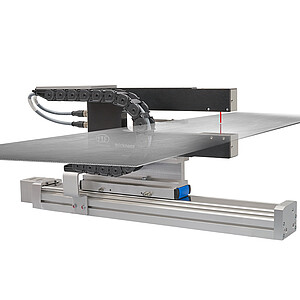

Operating principle of thickness measurement

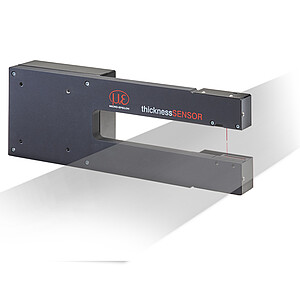

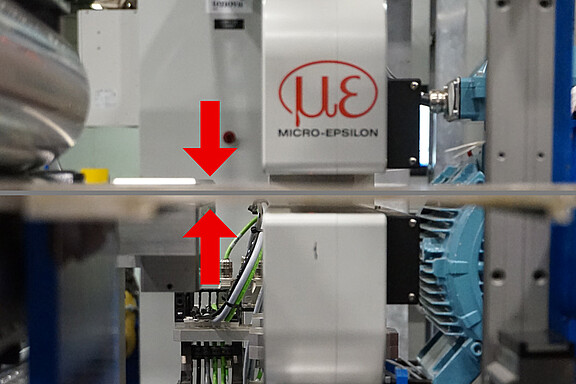

The principle of dimensional, geometric thickness measurement includes one optical distance sensor on each side of the material. The distance (=operating range) of both sensors is determined in a calibration process based on a certified measurement standard of which the thickness is added to the sum of the sensor signals in order to determine the current operating range. For thickness measurement during production, the difference between the sum of the distance signals and the value of the operating range is determined.

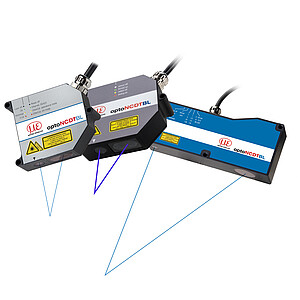

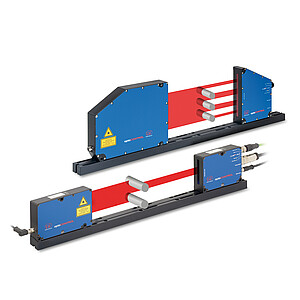

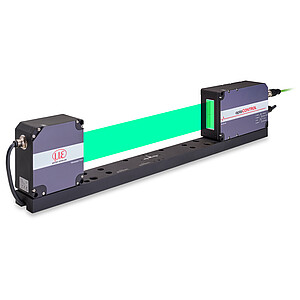

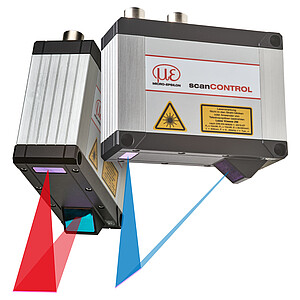

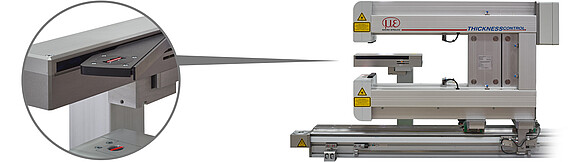

Depending on the application, the thicknessCONTROL systems are equipped with non-contact sensor technologies. Laser profile sensors have proved particularly successful, offering numerous advantages and are used in a variety of applications.

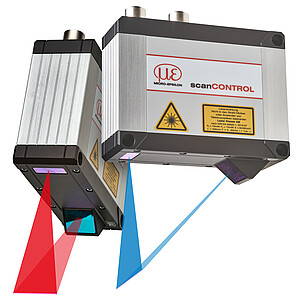

Leading role due to laser profile measurements

The thicknessCONTROL measuring systems can be equipped with different sensor technologies. In the aluminum and steel industry, laser profile scanners are the preferred choice with numerous advantages.

Advantages of laser profile sensors

- Environmentally friendly alternative to radiometric thickness measurement

- Free of isotope and X-ray radiation

- No consequential costs caused by hazardous waste

- No special safety measures (laser class 2)

- High measurement accuracy, even in harsh environments

- Large and small material thicknesses

- Independent of alloys, no specific calibration required

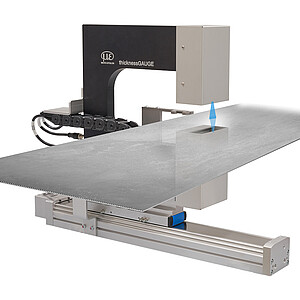

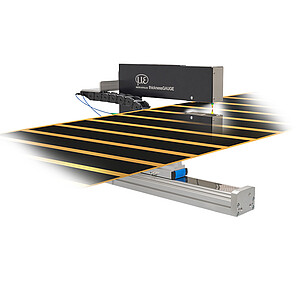

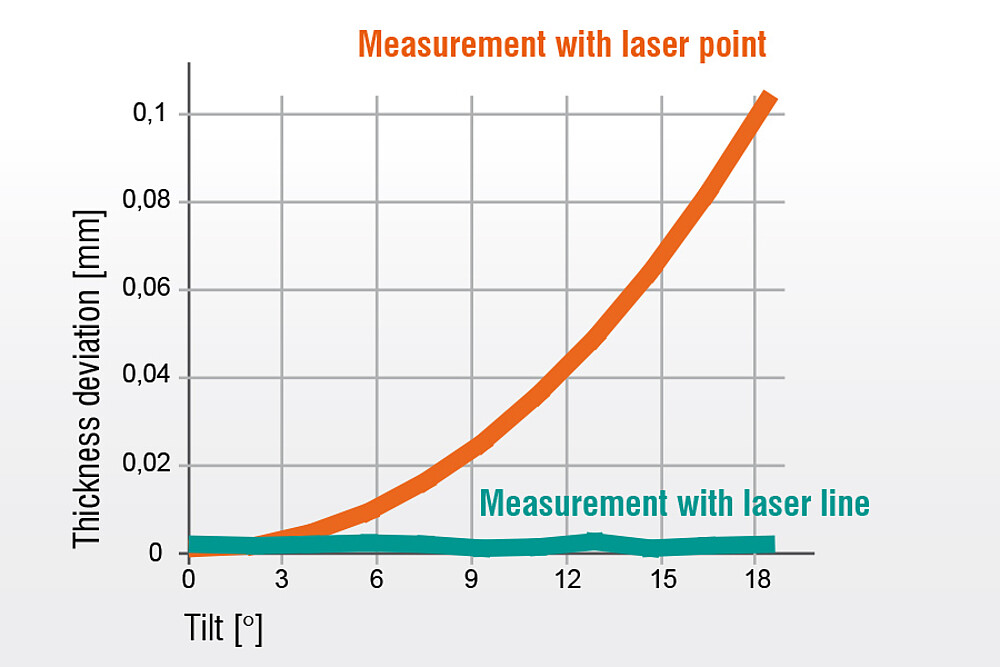

Innovative "Discrete laser line"

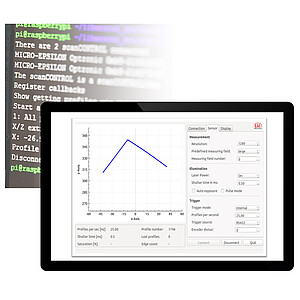

By using special lenses, a laser beam is enlarged to form a static laser line and is projected onto the target surface. A high quality optical system projects the diffusely reflected light of this laser line onto a highly sensitive sensor matrix which detects during one measurement, depending on the sensor, a profile with 640 or 1280 measuring points. From this matrix image, the integrated controller calculates the distance information (z-axis) and the position alongside the laser line (x-axis) in a two-dimensional coordinate system.

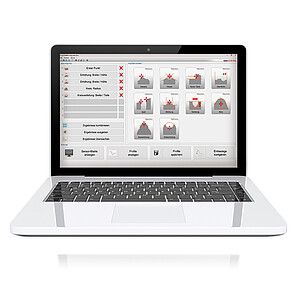

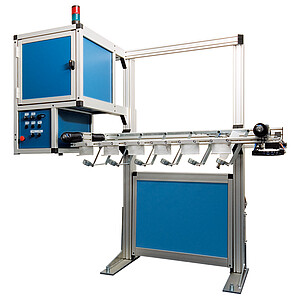

Automatic thickness calibration

Micro-Epsilon’s optical thickness measurement methods are alloy-independent and can be operated without material-specific calibration. In order to compensate for the effects of temperature fluctuations and to increase the accuracy, the thickness measuring systems are equipped with an in-situ calibration. For this calibration, either the reference or calibration part is fed or the C-frame is positioned. In addition, the in-situ calibration can verify the proper functioning of the system at any time. The analysis software enables fully automated test equipment capability monitoring.