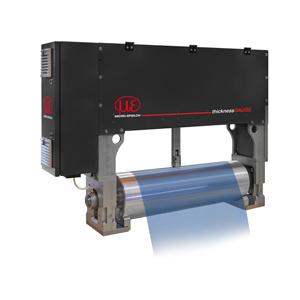

Surface inspection of mat components

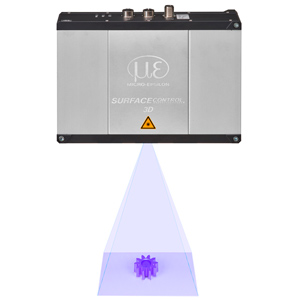

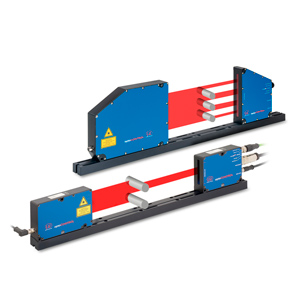

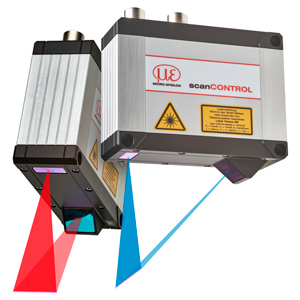

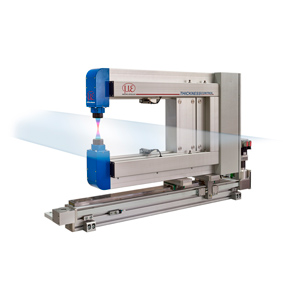

The requirements for the dismantling parts are just as high as for the actual body. The surfaceCONTROL 2500 is used for the defect detection of attachments and interior parts. This enables the objective and reproducible identification and classification of defects.

The surfaceCONTROL 2500 is used, for example, to inspect small parts such as fuel filler flaps, to detect defects on cockpit elements or for inspection in the press shop.

Characteristics

- Detection of a wide variety of surface form defects

- Objective evaluation of deviations (iO/niO decision)

- Clear definitions of defect criteria in supplier relationships

- Continuous process monitoring

- Minimization of rework as well as waste costs

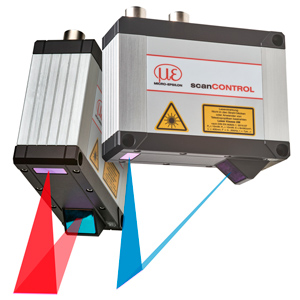

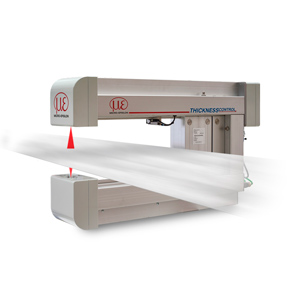

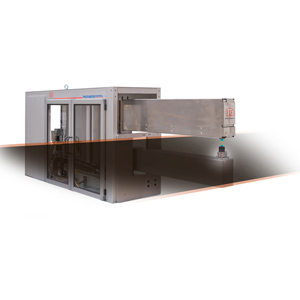

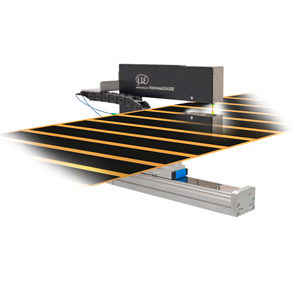

Surface inspection in the pressing plant

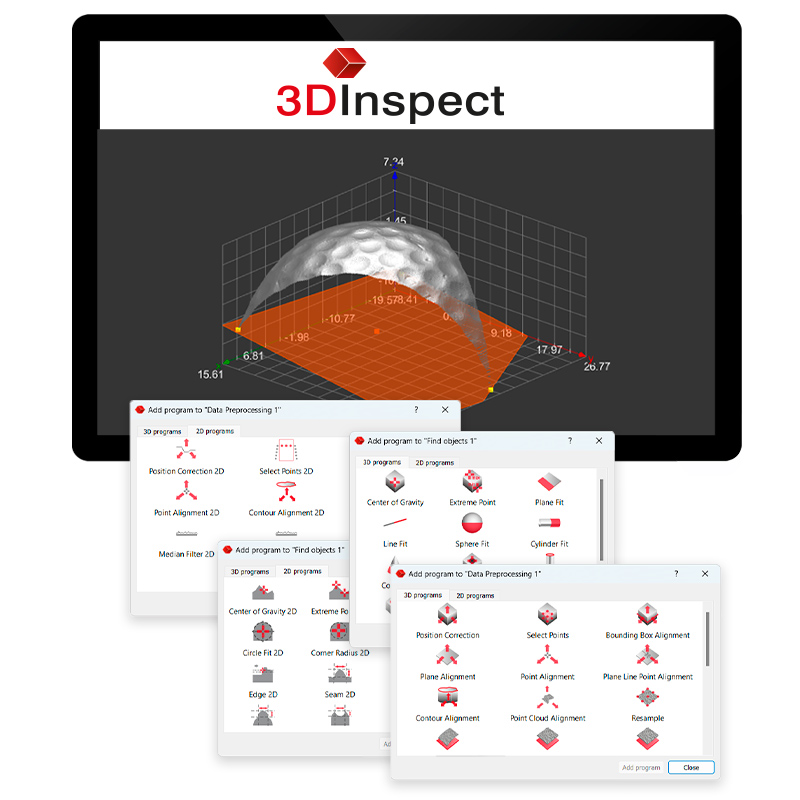

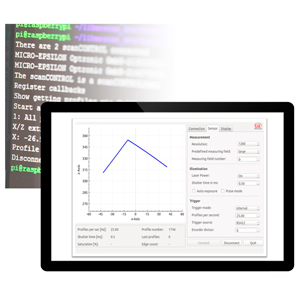

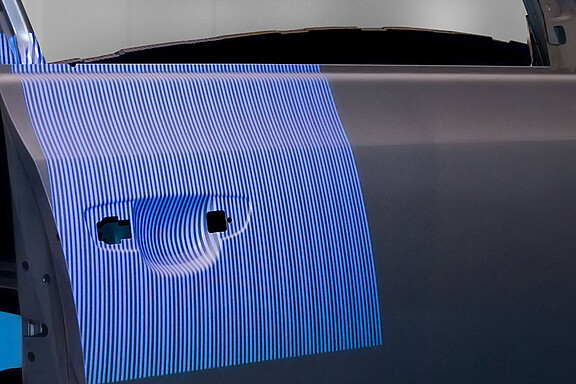

One of the main applications fields of surfaceCONTROL 3D sensors is the identification and analysis of deformations and discontinuity in automotive body shell parts. In modern stamping lines, automotive body shell parts are produced in a cycle time of a few seconds, which requires fast and precise inspection. With the surfaceCONTROL sensors, surface inspection of car body components is possible within just a few seconds. The powerful software package enables the identification and assessment of local defects with high accuracy.

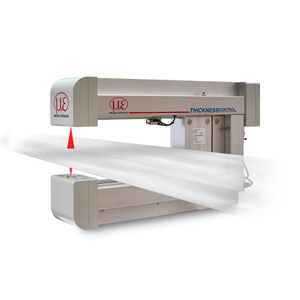

Inspection of interior plastic parts

The overall impression of a vehicle's quality is strongly influenced by its interior. In order to detect unwanted shape deviations in the instrument panel area, surfaceCONTROL 3D sensors are used. These sensors enable fast and objective assessment of surface deviations on both grained and smooth surfaces. For example, sink marks of the airbag or connection points can be reliably detected and evaluated.