Color sensor systems for material, surface, turbidity and gloss

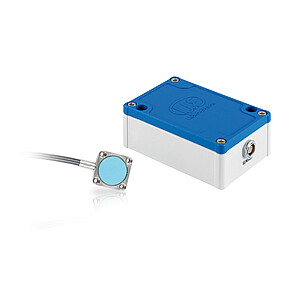

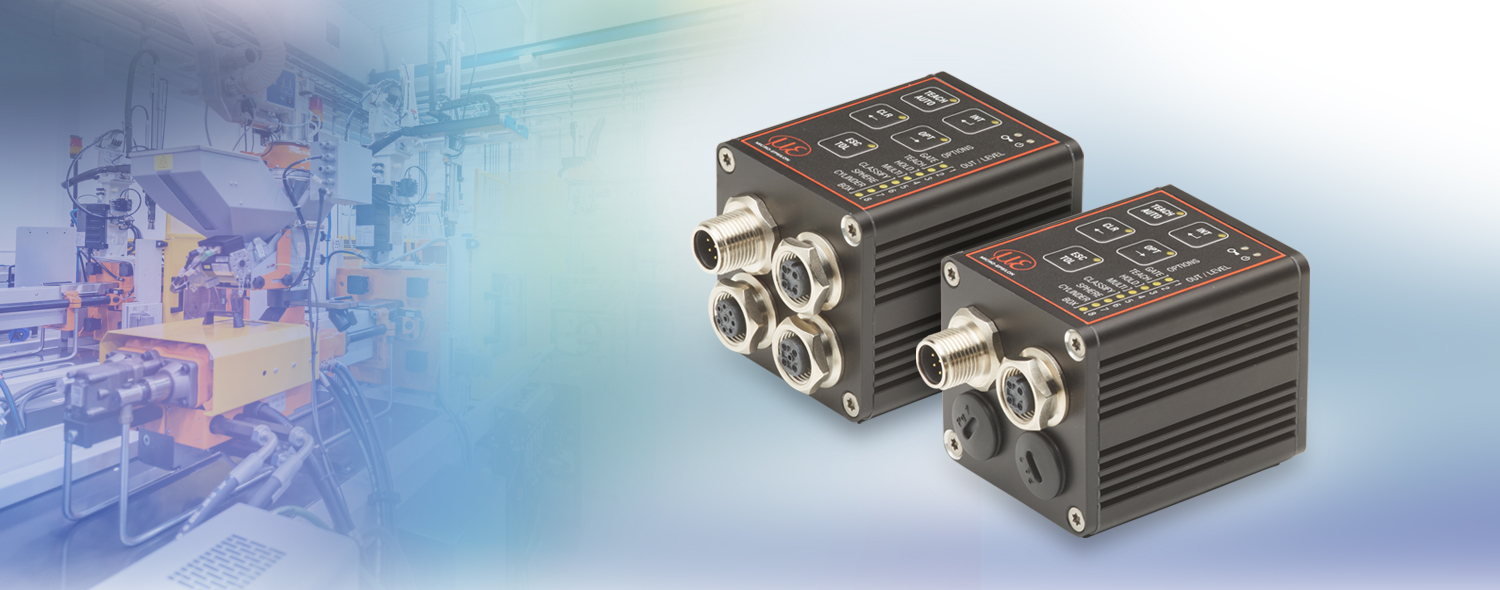

The colorSENSOR CFO is a new controller for precise color recognition in industrial measurement tasks. The CFO series is distinguished by high color accuracy, state-of-the-art interfaces and intuitive operation. The controller is connected to CFS sensors with integrated optical fibers, which can be adapted for different measurement tasks. The colorSENSOR CFO is used in color recognition tasks on interior parts such as head supports, in packaging control or in color sorting tasks with crown caps, closures or labels.

Characteristics

- High measurement speed up to 30 kHz for dynamic processes

- Fast output of measurement values (Lab/XYZ) up to 500 Hz

- Large color memory for different test batches

- Precise measurements with high color accuracy ΔE ≤ 0.3

- Color space: XYZ, xyZ, L*a*b*; L*u*v* or u'v'L*

- Light source: white light LED

- Ethernet, RS232 process interface and additional USB port for CFO200

- Options (100) for CFO100 & CFO200: Modbus (TCP/RTU) + Gateway: PROFINET, Ethernet/IP and EtherCAT

- Robust aluminum housing

- Protection class IP65

- Customer-specific calibration

- Ease of use via web interface

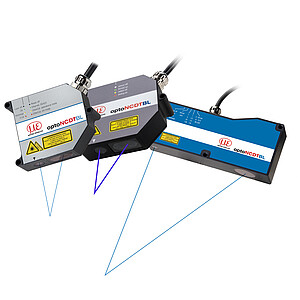

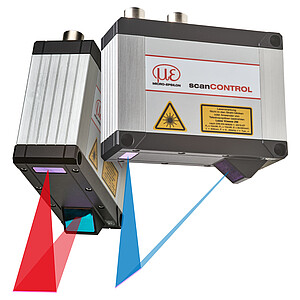

Highest precision for the distinction of slightest color differences

The sophisticated CFO controller enables the detection of slightest color differences. Its powerful light source combined with fiber optic sensors allows the distinction of colors on dark surfaces as well as on shiny, reflective and structured metals.

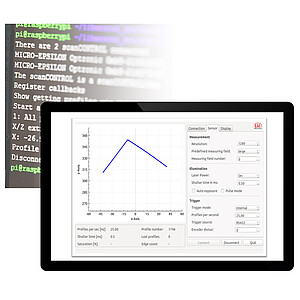

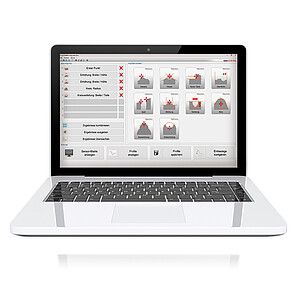

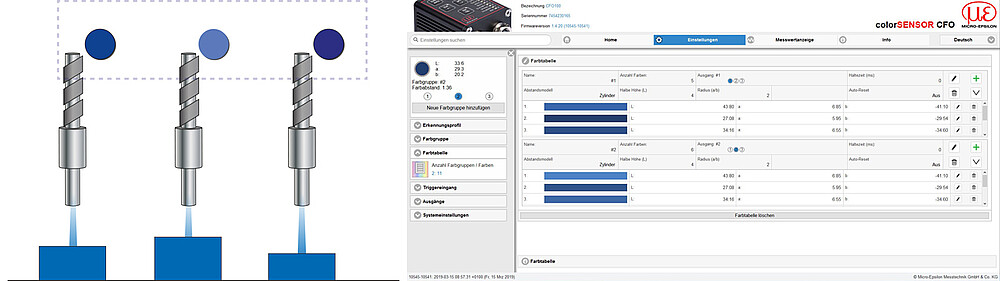

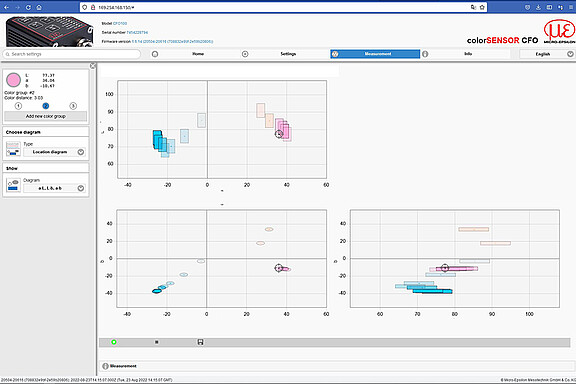

Intuitive operation via web interface

The integrated, intuitive web interface simplifies configuration of the CFO system. The sensor is connected to a PC via an Ethernet interface. The web interface features measurement value display, set up and configuration of e.g. exposure and measurement frequency. Furthermore, the sensor can be adapted to suit different color groups and tolerance space for each color.

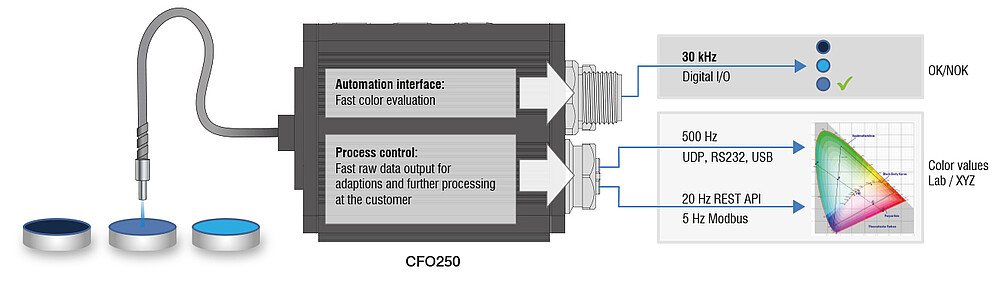

Fast output of measurement values

The colorSENSOR CFO performs an internal evaluation based on taught-in color values at up to 30 kHz and outputs the result via digital switching signals. In addition, the raw data can be transmitted directly to a PLC or machine system in Lab or XYZ at up to 500 Hz via a UDP, RS232 or USB interface. This can be done continuously or only on demand. Corresponding edge or level triggers also control for how long or how many measured values are output.

Powerful multi-teach feature

The multi-teach function allows for geometry-dependent color variants to be taught in color groups. Since the detected colors vary with different distances between sensor and measuring object, these color variants can easily be taught into a color group. Individual color groups can be created for different color shades.

Customer-specific calibration

In order to improve the recognition performance and to reduce deviating measurement values between several sensors for a certain configuration, customers can request a customer-specific calibration for the colorSENSOR CFO200. Therefore, the sensor and the controller are calibrated to the customer-specific reference target in the measurement arrangement required. A measurement deviation of Delta E < 1 between the individual systems can be achieved. Due to the calibration, the sensors are exchangeable and measure colors which have almost the same Lab values.