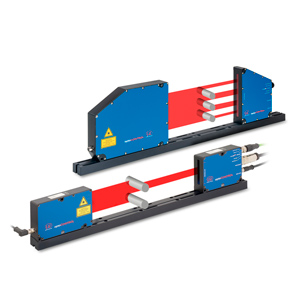

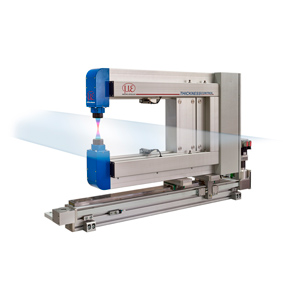

Industrial Performance Unit for automated 3D measurements

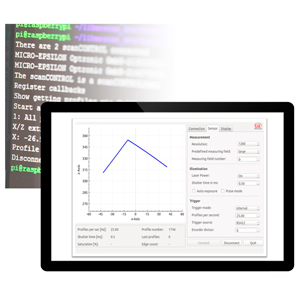

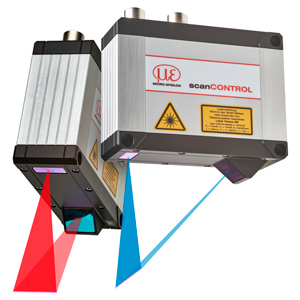

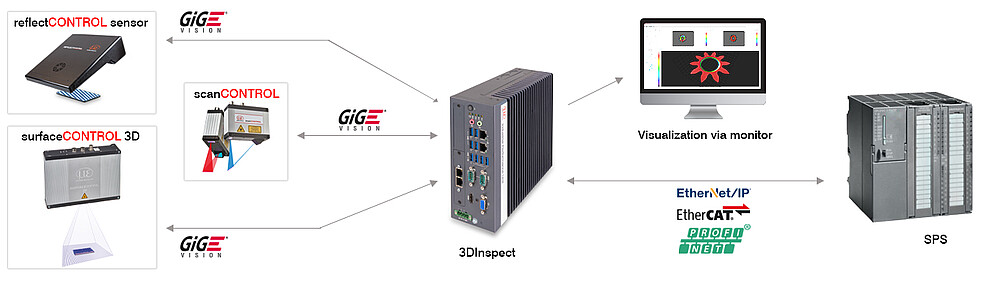

The Industrial Performance Unit is a powerful computing platform for the efficient commissioning of Micro-Epsilon 3D sensors. The fully compatible controller is ideally suited to inline processes in 3D measurement tasks. The intuitive 3DInspect software with Valid3D technology enables simple and fast sensor parameter setting, which allows measurements to start immediately. The Industrial Performance Unit directly processes three-dimensional data, which is subsequently evaluated and assessed via the 3DInspect software. Results can be output via the integrated PROFINET, EtherCAT and EtherNet/IP interfaces.

Characteristics

- Powerful solution for 3D measurement tasks

- Full compatibility for inline processes in customer applications

- Intuitive 3DInspect software with Valid3D technology included

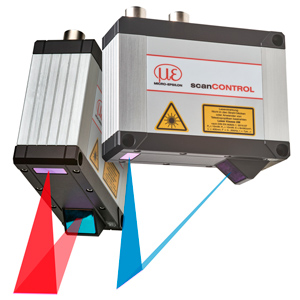

- Fast commissioning of Micro-Epsilon sensors

- Integrated interfaces: PROFINET, EtherCAT, EtherNet/IP

- Industrial-grade hardware with passive cooling

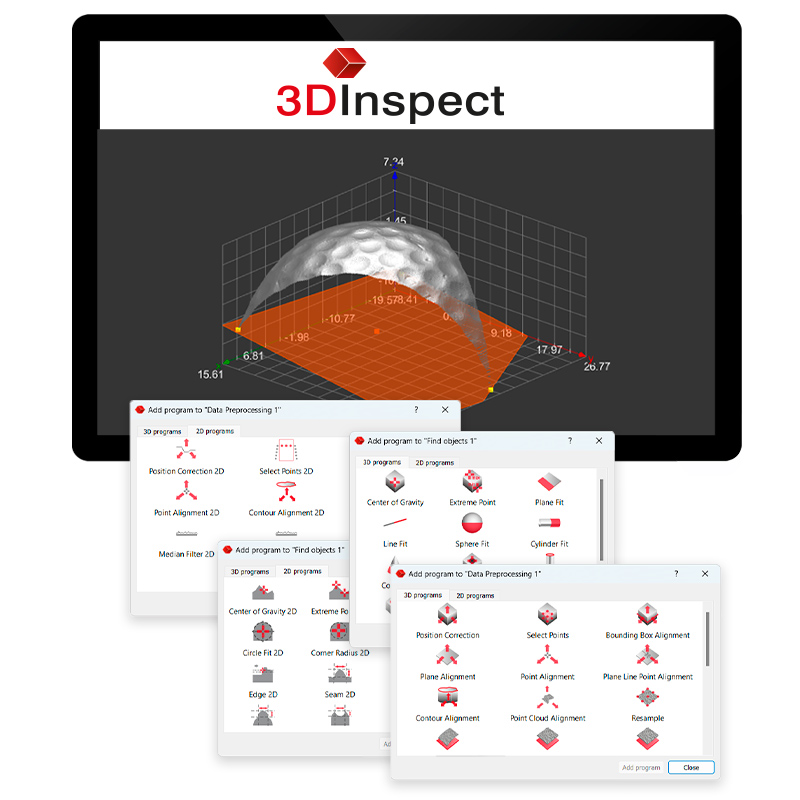

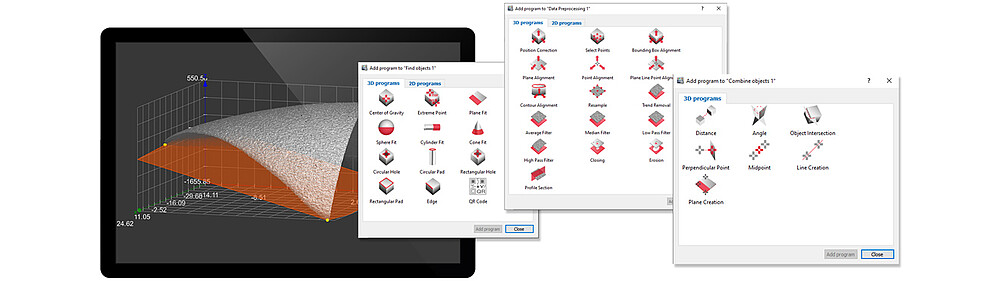

3DInspect: Powerful software for all Micro-Epsilon 3D sensors

3DInspect is a uniform and user-friendly software tool for all 3D sensors from Micro-Epsilon. Parameter setting of the 3D sensors and recording of the measurement data are done directly in the 3DInspect software. Powerful tools allow point cloud alignment and filtering, intuitive detection and selection of relevant areas, and program combination. The 3D point clouds can be processed as required and measured values can be output to the controller.

Inline capability for industrial applications

The flexible, industrial-grade hardware with passive cooling allows easy and space-saving installation. Therefore you can install this unit in a control cabinet or mount it directly in the machine. You can easily connect accessories such as monitor, keyboard and mouse.

Industrial Ethernet: Output of measurement values via integrated interfaces

The Industrial Performance Unit offers integrated interfaces for connection to the PROFINET, Ethernet/IP and Modbus/TCP industrial fieldbuses. Prepared device description files allow easy integration into the respective control environment. For reliable communication, the sequential control model developed by Micro-Epsilon is available for smooth commissioning. It is available as an implementation example for typical controllers.