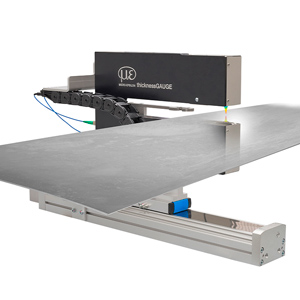

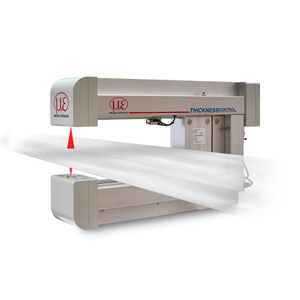

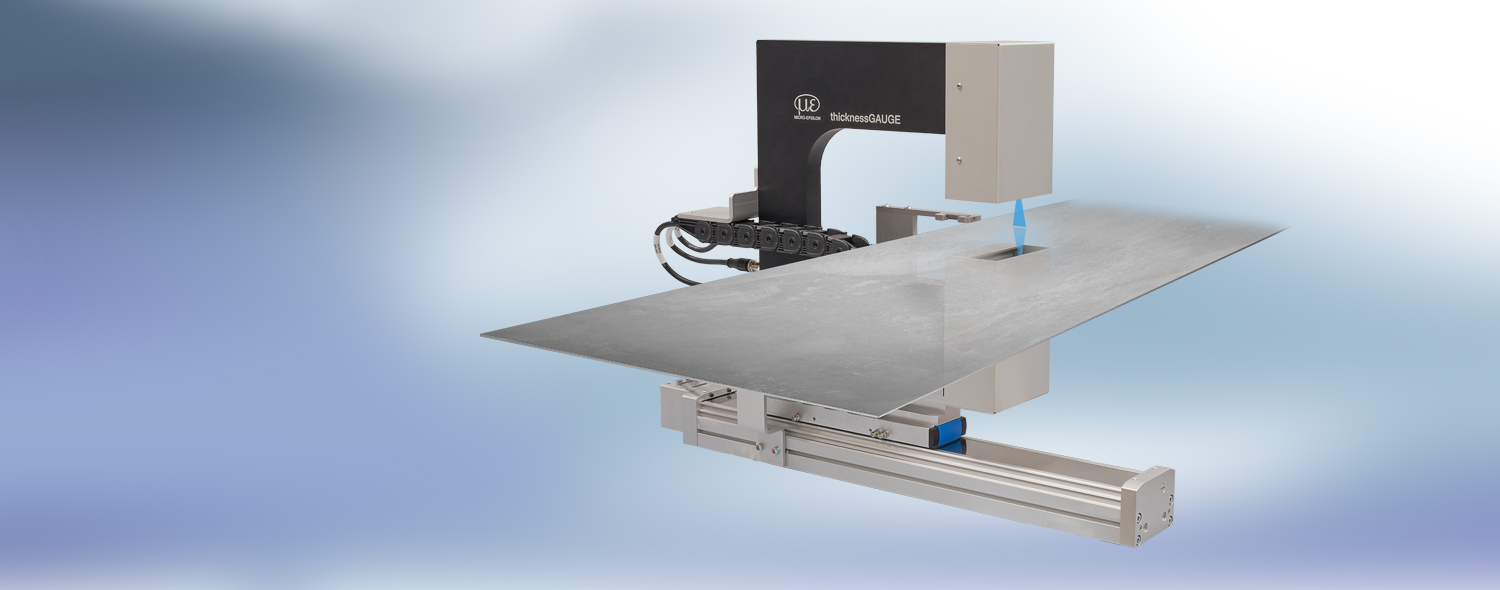

thicknessGAUGE C.LP

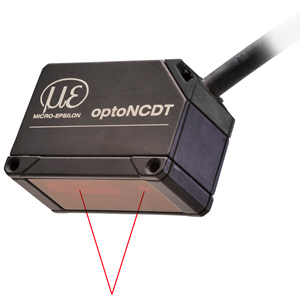

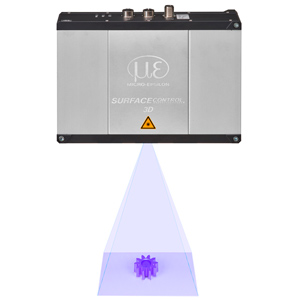

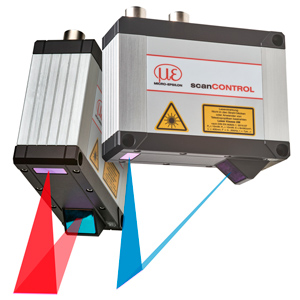

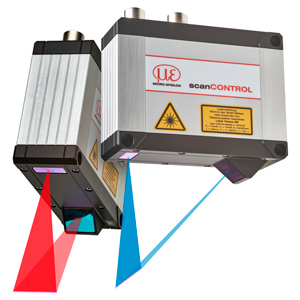

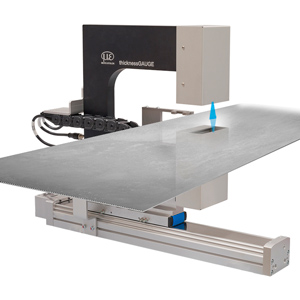

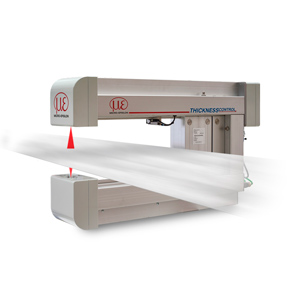

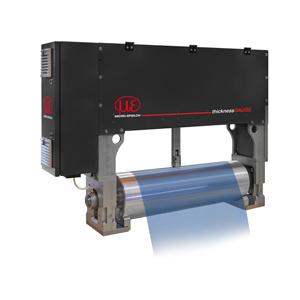

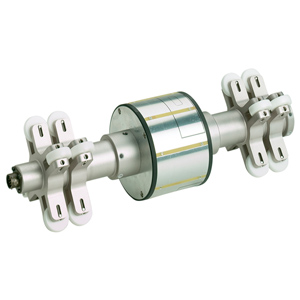

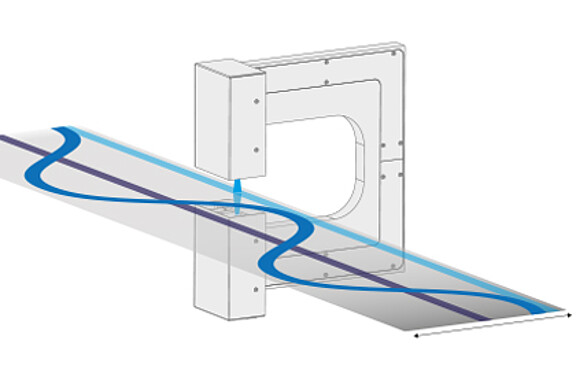

thicknessGAUGE C.LP sensor systems use laser profile scanners for the thickness measurement. These scanners project a laser line onto the surface to be measured. The laser line compensates for strip tilting and enables profile averaging. The laser line measuring technique makes it possible to measure the thickness of structured materials such as embossed surfaces and perforated plates.

Characteristics

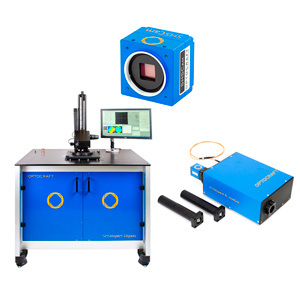

- Sensor technology used: Blue Laser profile sensors

- Measuring range (thickness): 15 mm

- Accuracy: ±1.2 µm

- Measuring rate: up to 100 Hz

- For structured materials, e.g., perforated and embossed plates

- Best-fit line possible

- Compensation for tilted strips

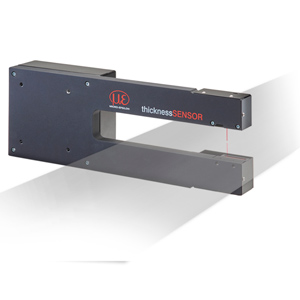

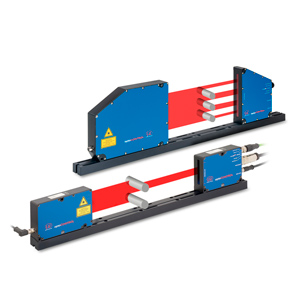

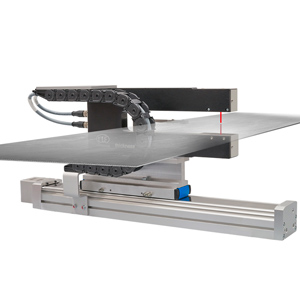

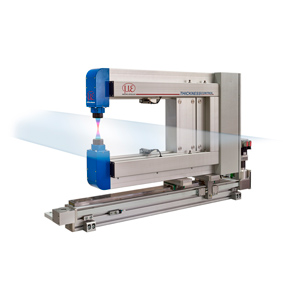

Precise thickness measurement using laser profile scanners

The thicknessGAUGE C.LP sensor systems are assembled ready for operation and calibrated at the factory. They consist of a stable frame with two laser scanners attached to it. These scanners measure the thickness of the measuring object according to the difference principle. The laser scanners are perfectly adjusted to each other in terms of their mounting conditions, therefore providing high measurement accuracy.

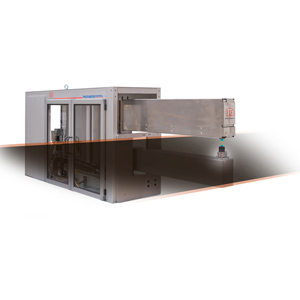

A linear axis moves the sensor system from the parking position to the measuring position. For fully automatic calibration, the system is moved back to the parking position

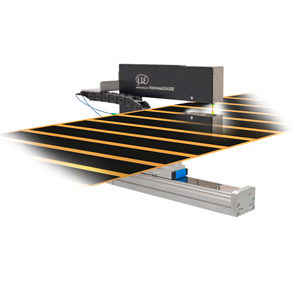

.The thicknessGAUGE C.LP sensor system is used for precise thickness measurements of strips and plates. It can also be used for fixed track measurements, e.g., for center-line measurements (center thickness) or for thickness measurements on the edges. A linear unit enables traversing thickness measurements up to 600 mm strip width.