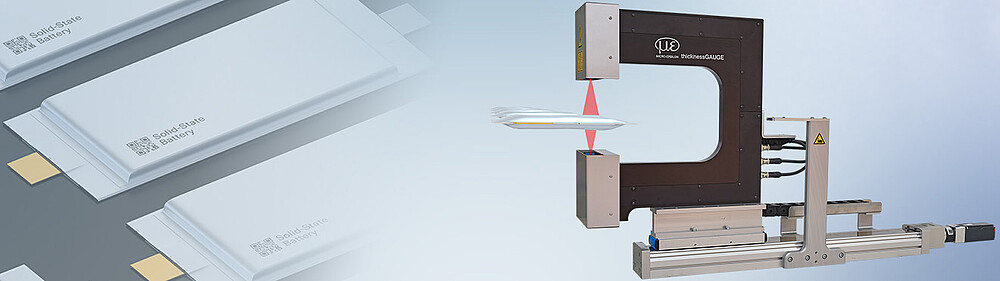

Inline 3D measurement of welded pouch cells

In battery cell production, precise control of welded pouch cells is crucial for their safety, performance and service life. The thicknessGAUGE 3D enables high-resolution inline inspection of these sensitive components – directly in the production process, fully automated and non-contact.

The measuring system is based on two powerful laser scanners that detect the finest profile information during a linear movement. This profile data is merged into a detailed 3D point cloud. Based on this point cloud, the thicknessGAUGE 3D calculates freely programmable target values that enable both simple 2D dimensions and complex 3D geometries to be checked quickly and precisely.

Fields of application:

- Seam inspection of welded cell edges

- Thickness measurement across the entire cell surface

- Detection of pouch shell deformations

- Positioning control of taps and contacts

Advantages:

- Turnkey sensor system for geometry inspection and 3D measurement in the line

- Compact design

- Powerful software package