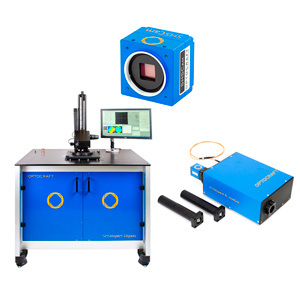

3D quality inspection in coordinate measuring machines

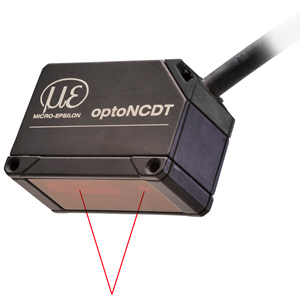

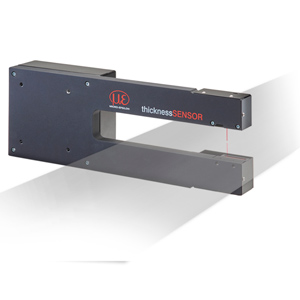

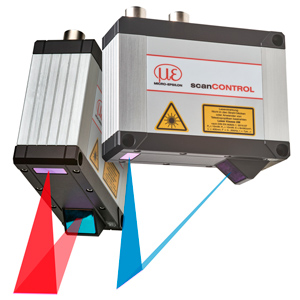

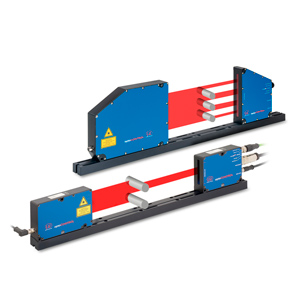

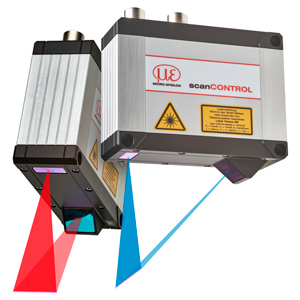

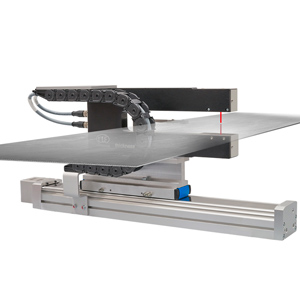

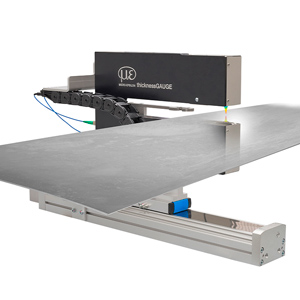

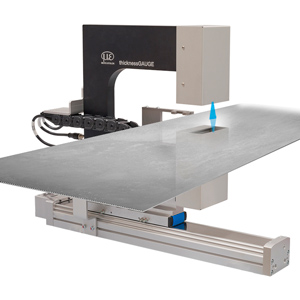

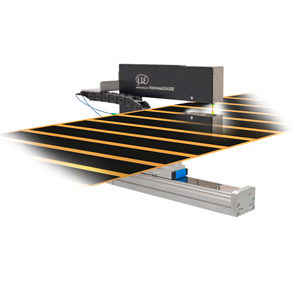

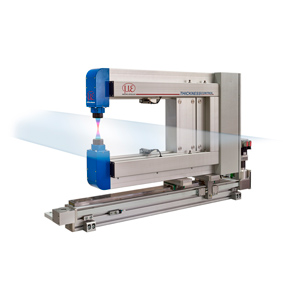

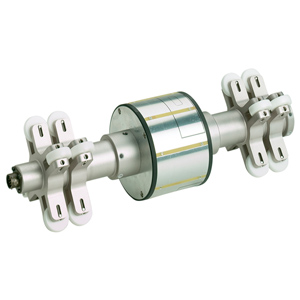

The generation of 3D point clouds in coordinate measuring machines (CMM) is used both for quality inspection and for reverse engineering. Laser profile scanners from the scanCONTROL series detect the geometric shape of objects by moving them mechanically across the measuring table. A special CMM trigger in the sensor ensures precise synchronization of the measuring time with the current measuring position, enabling recording without a time delay. This increases the accuracy of measurements from different directions during movements.

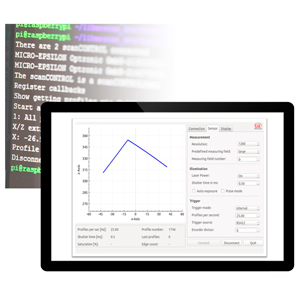

The sensor transmits the recorded raw data in the highest quality and in accordance with the GigE Vision standard into an overall coordinate system. This is done at a high speed of up to 10 million points/second. Thanks to the compact dimensions of the sensor, low weight, and integrated controller, the measurement setup is extremely space-saving. At the same time, these properties enable high movement speeds and flexible integration in various applications.

The wide variety of scanCONTROL sensor models enables adaptation to different table and object sizes and materials. Due to the large number of available interfaces, the sensor can be operated with almost any table control unit.