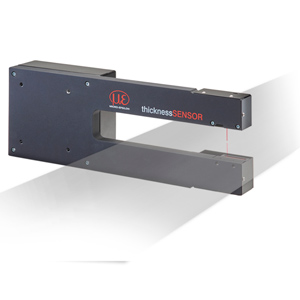

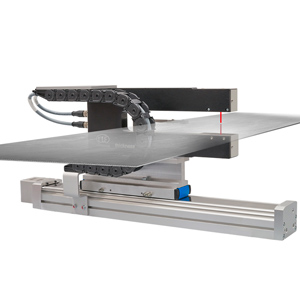

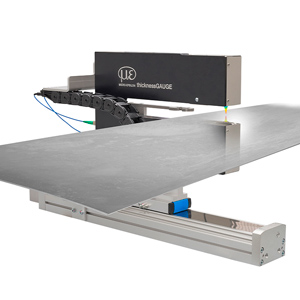

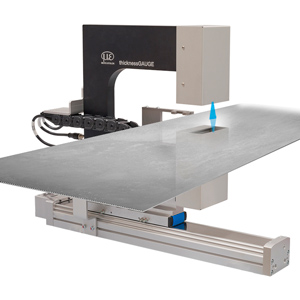

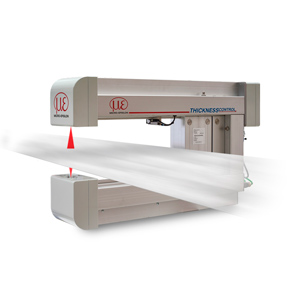

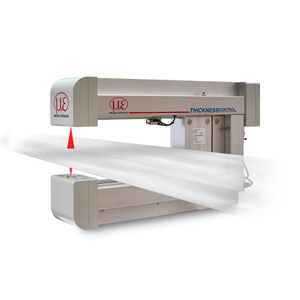

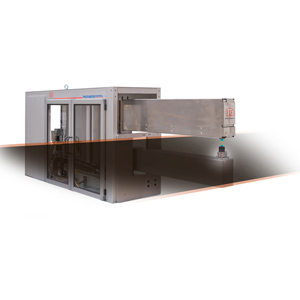

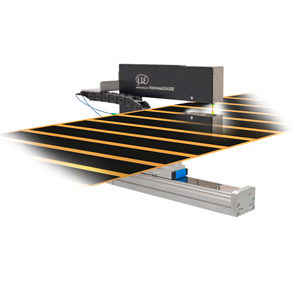

Belt stabilization in hot-dip coating lines

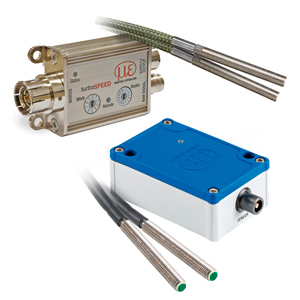

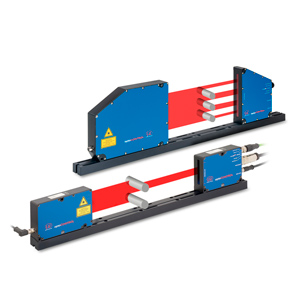

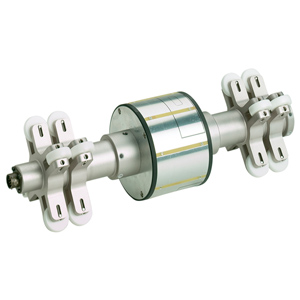

In hot-dip coating lines, steel strips are coated with liquid zinc, zinc alloys and aluminum alloys in a continuous process. Due to the high speed of the belts, vibrations occur. To minimize these, electromagnetic stabilization systems from the market leader EMG are used, in which 10 to 16 inductive sensors of type EU40 from Micro-Epsilon are installed.

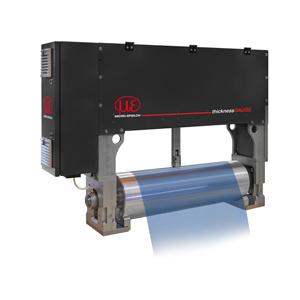

Robust eddy current measuring system for demanding environmental conditions

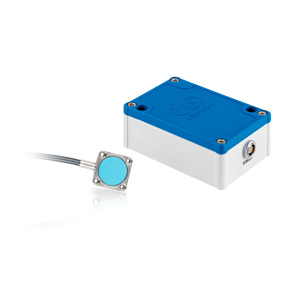

During the coating process, the sensors detect the vibrations as distance values without contact. These are transmitted to the electromagnetic stabilization system, which enables continuous monitoring of the entire system and thus ensures a reliable reduction in vibrations. The inductive sensors are extremely robust and can easily withstand the high temperatures and chemical and mechanical stresses of the system. They work with a large measuring range of 40 mm and are operated with the compact eddyNCDT 3020 industrial controller in a version adapted exclusively for the application and EMG (DT3029/EMG). The controller is also extremely robust and designed with a high IP67 protection class. Thanks to its compact design and high temperature resistance up to 105 °C, it can be integrated directly into the stabilization unit.

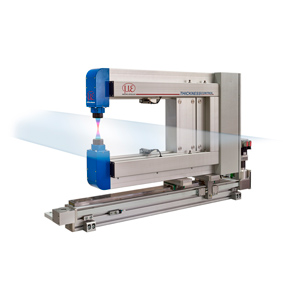

Precise measurement results

High EMC immunity ensures that the sensor controller unit delivers stable measurement results even in the vicinity of electromagnets. Thanks to the short cable length of 1 m and the excellent temperature stability of the system, the precision and stability of the output signal is increased enormously. This is transmitted to the control unit up to 50 m away via the analog current output. The precision and robustness of the Micro-Epsilon system help to significantly increase the quality of the end products.