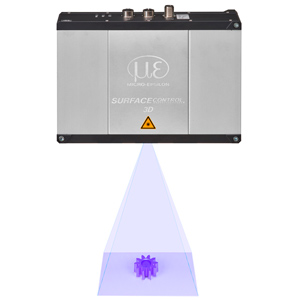

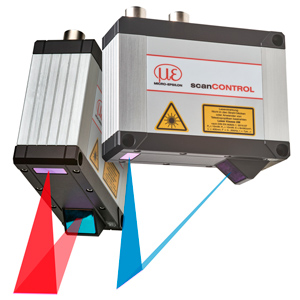

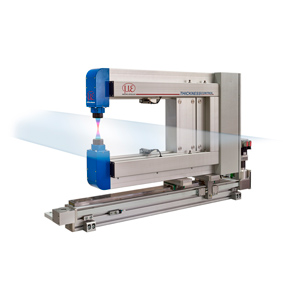

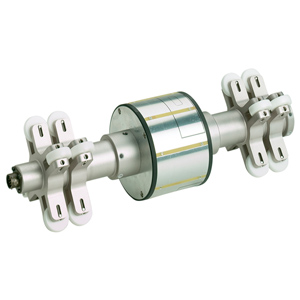

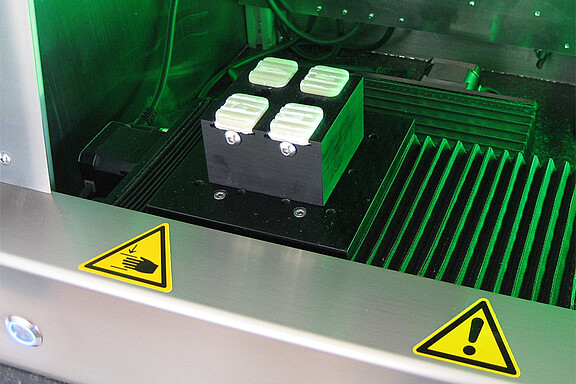

Medical technology

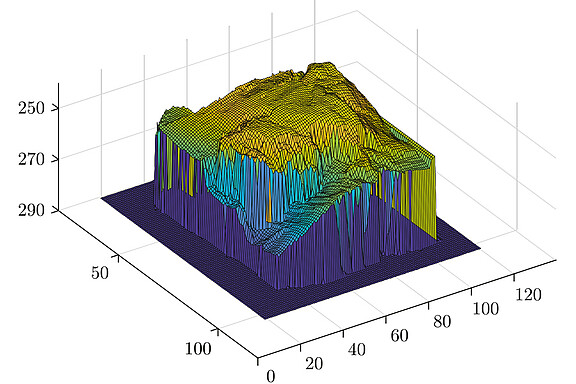

In medical technology, high standards apply with regard to quality, repeatability and compliance with narrow tolerances. These also apply for medical devices and apparatus construction, plant automation, the manufacture of medical technology products and the development and production of pharmaceuticals.

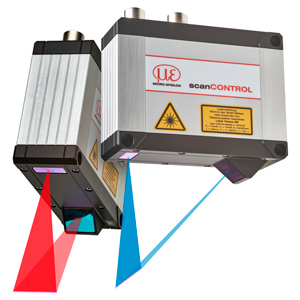

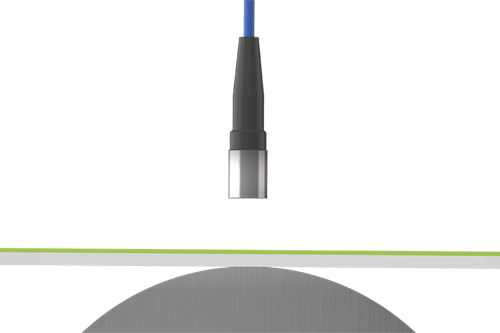

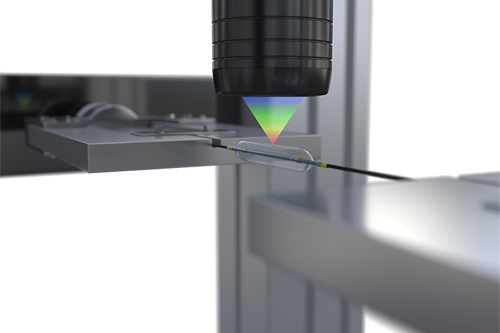

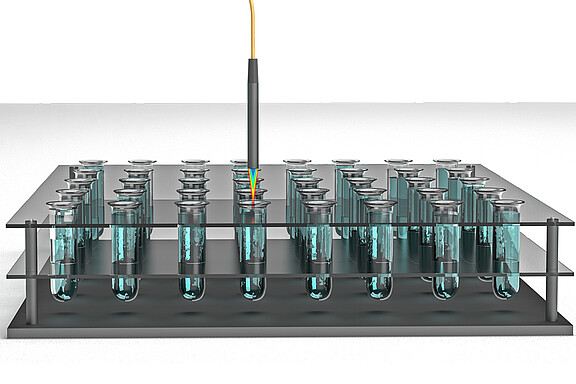

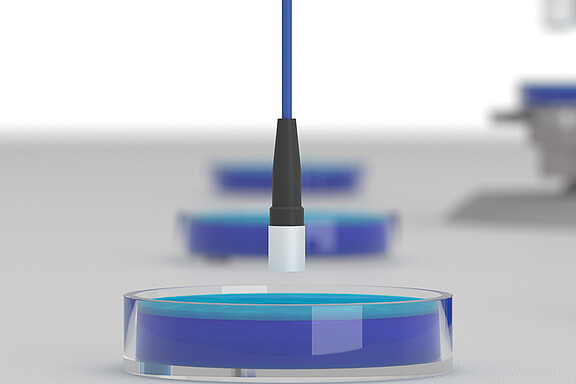

Thanks to high accuracy, integrability and the wide variety of models, sensors from Micro-Epsilon are used in versatile measurement tasks.