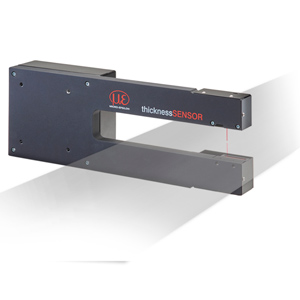

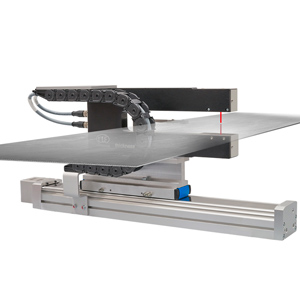

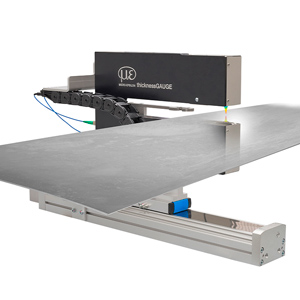

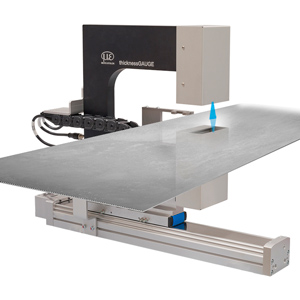

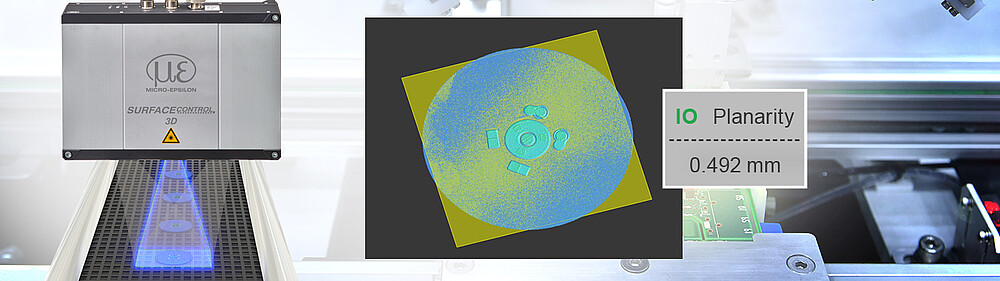

Planarity testing of substrates

Electronics production places particularly high demands on manufacturing accuracy - especially when it comes to the planarity of substrates such as printed circuit boards (PCBs) and flexible printed circuits (FPCs). Even the smallest deviations can severely disrupt the machining process.

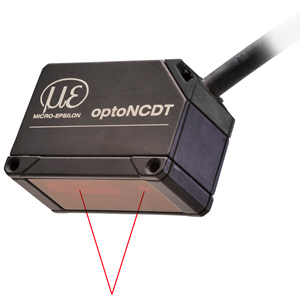

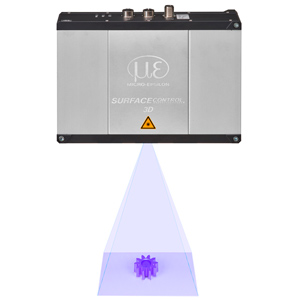

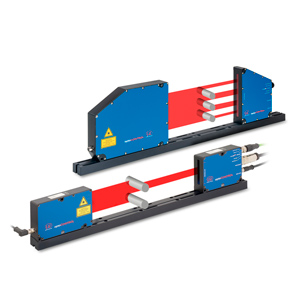

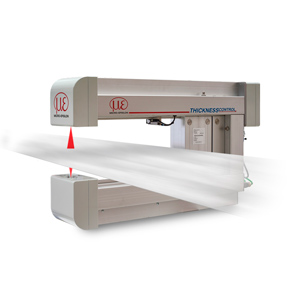

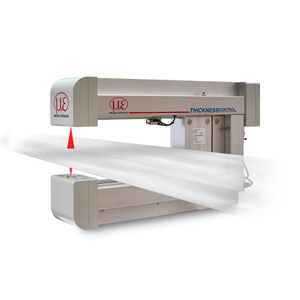

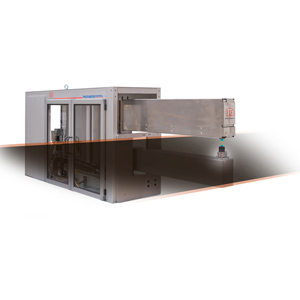

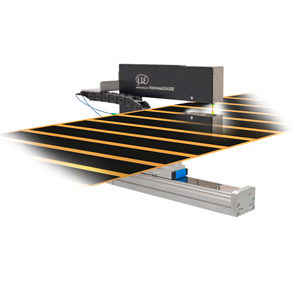

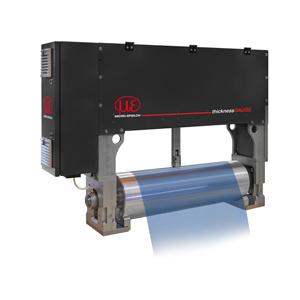

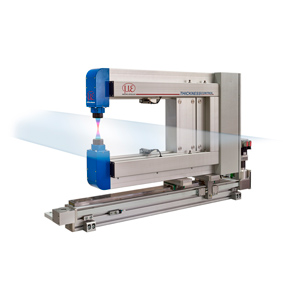

The high-resolution surfaceCONTROL 3D sensors are used for reliable planarity testing. These detect even the finest height differences with the utmost precision and thus enable a full-surface analysis of the substrate evenness - inline and in real time. At the same time, they can be seamlessly integrated into existing production and automation lines, ensuring a consistent, quality-assured process.

The surfaceCONTROL 3D sensors capture entire surfaces in a single shot. A high-resolution point cloud is generated from the 3D snapshots, which forms a digital elevation model of the surface. The repeatability of up to 0.25 µm that is achieved allows the detection of the finest planarity deviations. Different measuring fields also enable adaptation to substrates of various formats and geometries.

The sensors offer a powerful interface architecture for integration into automated production lines. In addition to Gigabit Ethernet for fast data transmission, they have digital I/O ports and an optional gateway that enables connection to industrial fieldbuses such as PROFINET, EtherCAT and EtherNet/IP. The high measuring speed enables use in stop & go processes on belts or rotary indexing tables.