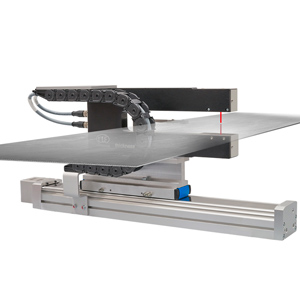

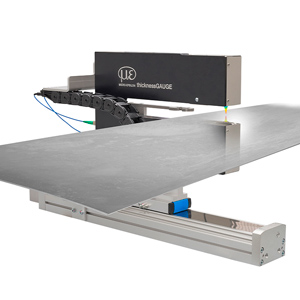

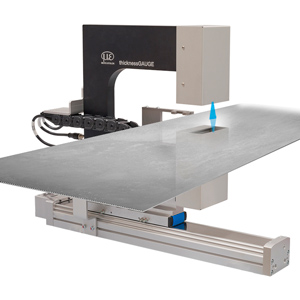

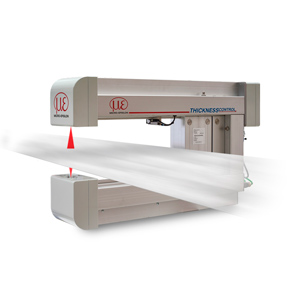

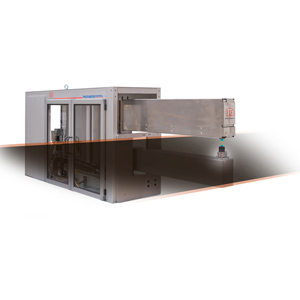

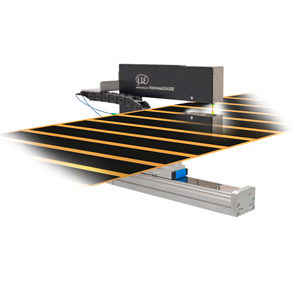

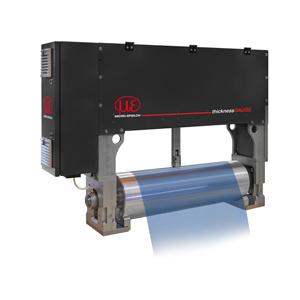

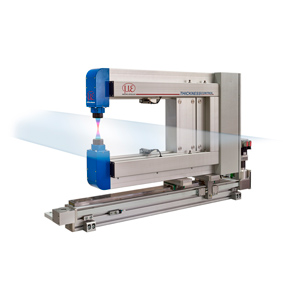

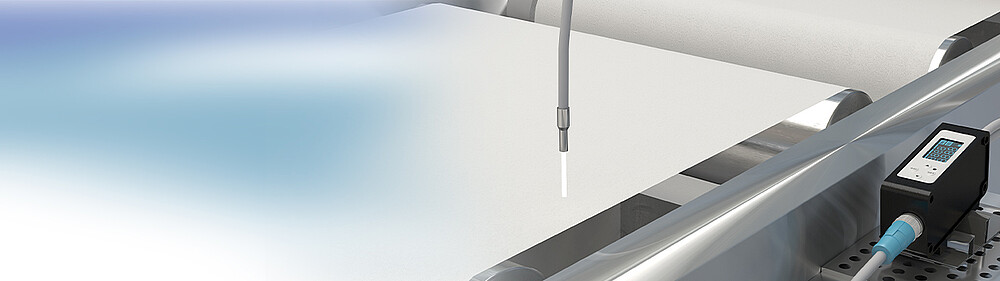

Inline breakage monitoring of belt material

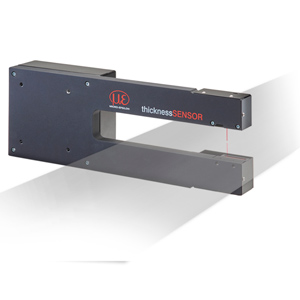

Steel strip coils and steel wire coils are semi-finished products that are used between rolling mills and in the processing industry. The coils, which weigh several tons, consist of coiled strips of material that must be checked for integrity before further processing. Reliable breakage monitoring is essential, as even small cracks or material defects can cause expensive downtimes or rejects. Classic challenges in breakage monitoring include early detection of the smallest defects, reliable detection at a high material speed and the stability of the measurement under challenging environmental conditions such as heat or humidity.

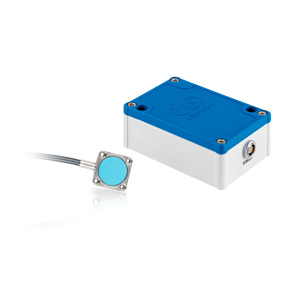

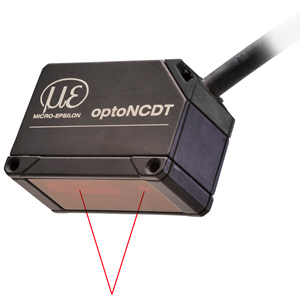

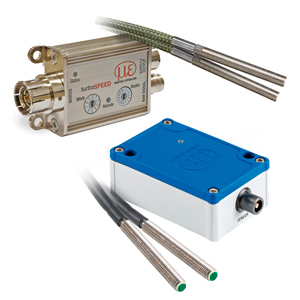

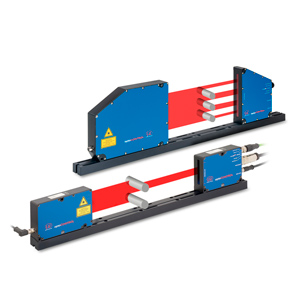

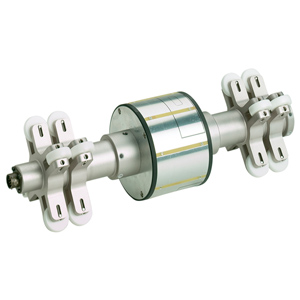

To solve these tasks quickly and easily, the processing industry relies on Micro-Epsilon sensors from the optoCONTROL CLS1000-AU-PP series in combination with the CFS4-A30 reflex sensor. These fiber optic sensors are characterized by a short response time of just 100 μs, which means that defects such as cracks in the belt material can be detected quickly. In addition, the high switching frequency up to 2.5 kHz enables precise output of the signal through the analog output. With a large detection range up to 430 mm, the sensors can be mounted outside the immediate application area, which increases the service life and prevents damage.

The combination of inline measurement with a frequency up to 10 kHz, fast detection and robust design offers numerous benefits for breakage monitoring. The sensors provide reliable measurement results even at high temperatures and in humid environments and can detect defects early, even at high material speeds. This sensor solution therefore makes a significant contribution to quality assurance and minimizes downtimes in the production process.