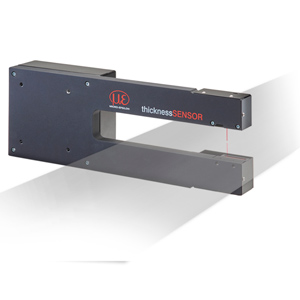

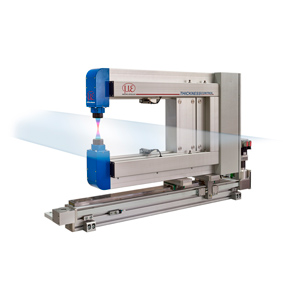

White light interferometer for stable thickness measurement with submicron accuracy

The new IMS5400-TH white light interferometer opens up new perspectives in industrial thickness measurement. The controller offers an intelligent evaluation feature and enables the thickness measurement of transparent objects with highest precision.

Characteristics

- Nanometer-precise thickness measurement and multi-layer thickness measurement even with varying distances and vibrating targets

- Stable measurement from a large distance, even of antireflection-coated targets

- Industry optimized sensors with robust metal housing and flexible cables

- Measuring rate up to 6 kHz for high speed measurements

- Easy configuration via web interface

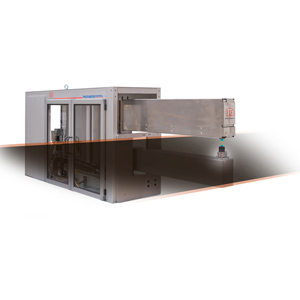

- Flexible industrial integration for fast field adaptation on site

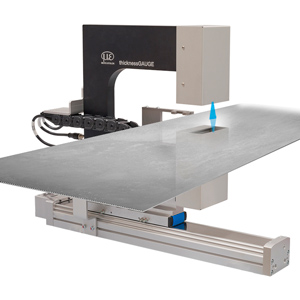

Stable thickness measurement with varying measurement distances

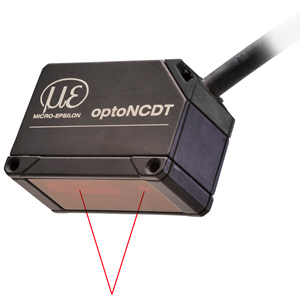

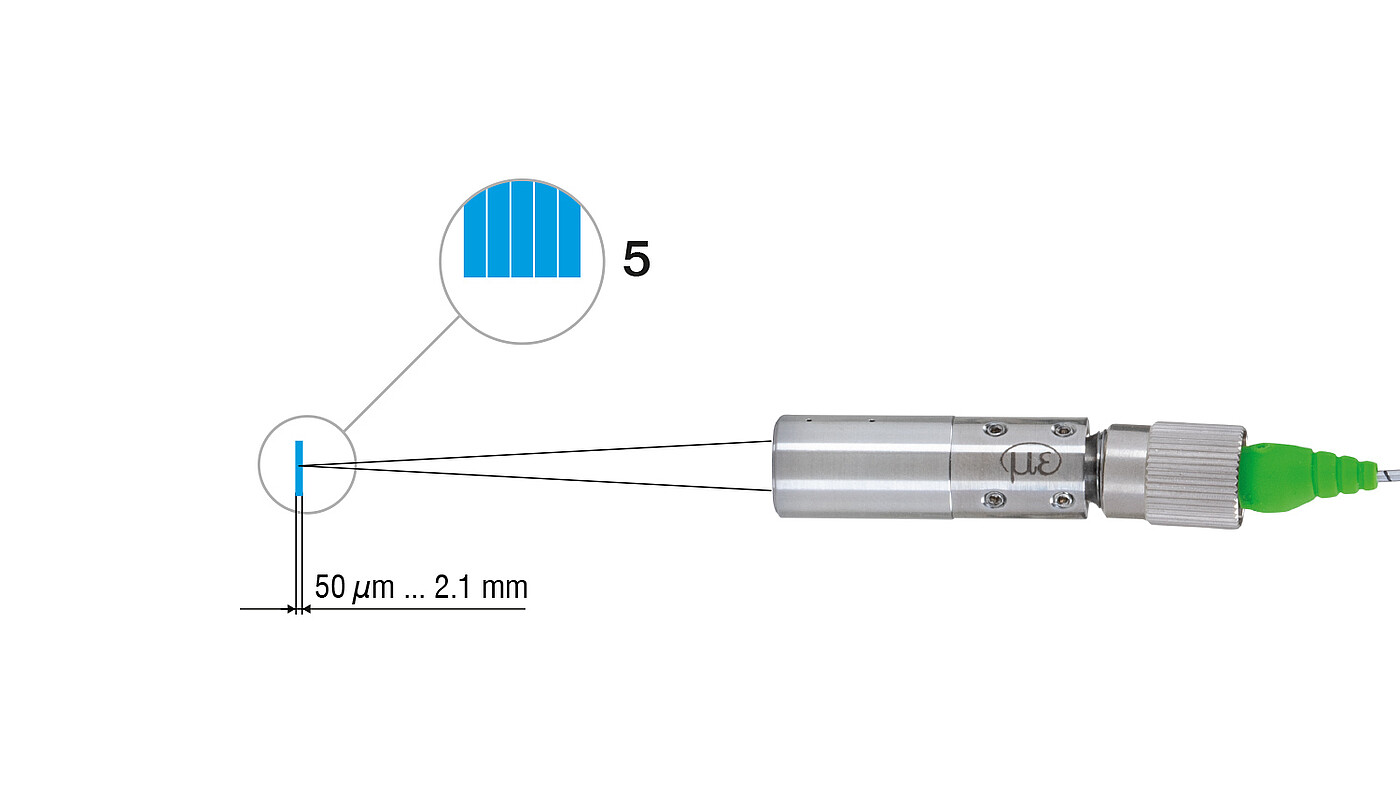

The IMS5400-TH white light interferometer is used for highly accurate thickness measurements from a relatively large distance. A decisive advantage here is the distance-independent measurement, where a nanometer-accurate thickness value is achieved even with moving objects. The large thickness measuring range allows the measurement of thin layers, flat glass and films. Since the white light interferometer works with an SLED in the near infrared range, thickness measurement of anti-reflective coated glass is also possible.

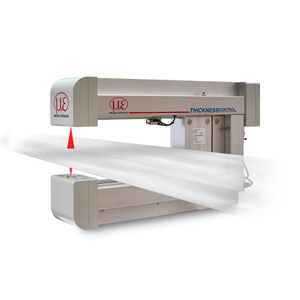

Multi-layer thickness measurement

With the multi-peak controller variant, several signal peaks can be evaluated simultaneously. This allows multi-layer thickness measurement of transparent objects and laminated glass. The controller outputs the thickness values with the highest stability regardless of their position.

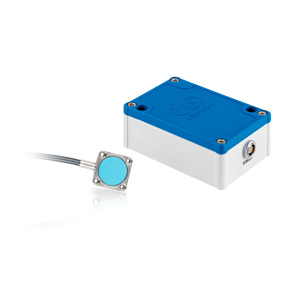

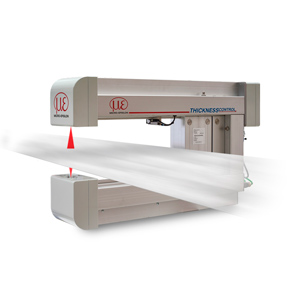

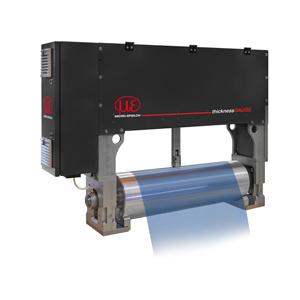

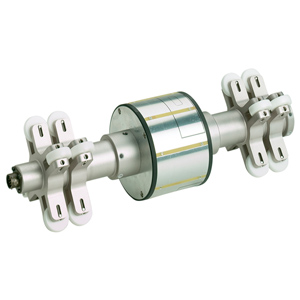

Ideal for industrial environments

Robust sensors and a controller in a metal housing make the system ideally suitable for integration into production lines. The controller can be installed in the control cabinet via DIN rail mounting and provides very stable measurement results due to active temperature compensation and passive cooling. These compact sensors are extremely space-saving and have highly flexible fiber optic cables. Cable lengths up to 10 m allow a spatial separation of sensor and controller. The sensor can be aligned easily and quickly using the integrated pilot laser. Commissioning and parameterization are conveniently performed via web interface and do not require any software installation.

Numerous models for demanding measurement tasks

| Model | Measuring range / Start of measuring range |

Linearity | Number of measurable layers | Fields of application |

|---|---|---|---|---|

| IMS5400-TH45 | 0.035 ... 1.5 mm (for BK7, n=1.5) / approx. 41.5 mm with an operating range of approx. 7 mm |

±100 nm | 1 layer | Industrial inline thickness measurement e.g. in flat glass production of single-layer glass |

| IMS5400-TH45/VAC | Inline thickness measurements in clean room environments and vacuum e.g. in display production for gap measurement in vacuum | |||

| IMS5400MP-TH45 | ±100 nm | Up to 5 layers | Industrial inline multi-layer measurement e.g. in flat glass production of multi-layer glasses |

|

| IMS5400MP-TH45/VAC | Inline multi-layer measurements in clean room environments e.g. in display production for multi-layer measurement in vacuum | |||

| IMS5400-TH70 | 0.035 ... 1.5 mm (for BK7, n=1.5) / approx. 68 mm with an operating range of approx. 4.2 mm |

±200 nm | 1 layer | Industrial inline thickness measurement e.g. in film production of single-layer films |

| IMS5400MP-TH70 | ±200 nm | Up to 5 layers | Industrial inline multi-layer measurement e.g. in film production of multi-layer films |

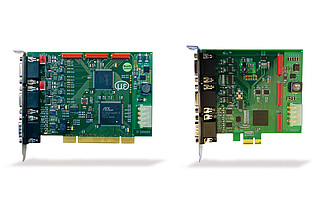

Interface and signal processing units

Modern interfaces for integration into machines and systems

The controller offers integrated interfaces such as Ethernet, EtherCAT and RS422 as well as additional encoder connections, analog outputs, synchronization inputs and digital I/Os. When you use Micro-Epsilon's interface modules, PROFINET and EthernetIP are available. This allows the interferometer to be integrated into all control systems and production programs.