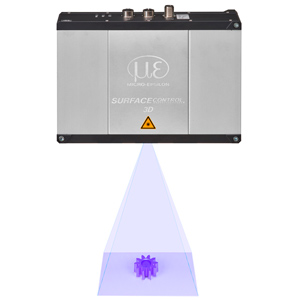

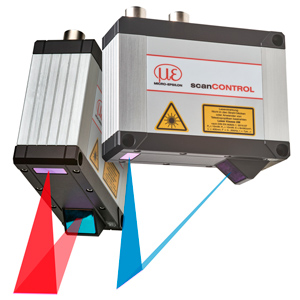

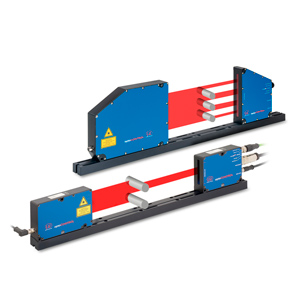

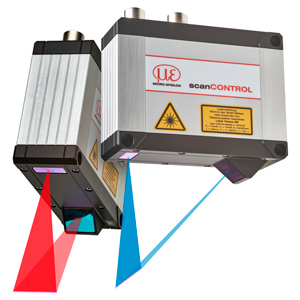

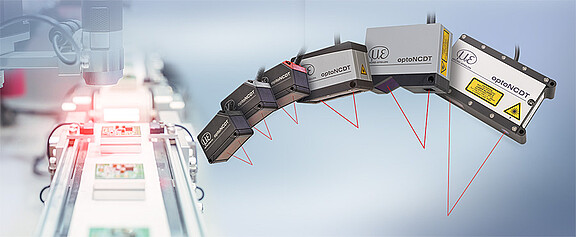

With the optoNCDT laser sensors, Micro-Epsilon offers a broad portfolio with measuring ranges from 2 to 1000 mm. This makes these sensors suitable for a variety of applications in a wide range of industries. Thanks to smart interfaces and robust, robot-compatible cables, they can be easily and flexibly integrated into industrial automation processes. Depending on the model, these include analog (U/I), RS422, Ethernet, EtherCAT, PROFINET, EtherNet/IP and IO-Link. The lasers measure precisely and reliably on almost all surfaces: matt, metallic or glossy. There are variants for particularly challenging measuring conditions:

- The "LL" versions with an oval light spot minimize optical disturbances (interference) and make it easier to measure on shiny materials.

- The "BL" models use the patented blue laser line principle, which is ideal for organic, (semi-)transparent or red-hot objects such as hot metals.

- Standard models use laser class 2. Class 3 lasers are optionally available for achieving better measurement results on dark surfaces as well as class 1 lasers for minimizing safety risks.

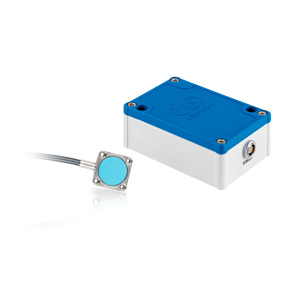

Miniaturization for series applications

The optoNCDT 1220, 1320 and 1420 models are ideal for applications involving large quantities. These models offer an excellent price-performance ratio and are particularly suitable for displacement, distance and position measurements in industrial automation – for example in machine building, in 3D printers or on robot arms. Their compact design with an integrated controller allows for easy installation even in tight spaces and they are easy to set up via a web interface. In addition, the integrated active surface compensation (ASC) ensures that the measurement signal remains stable – regardless of the color or brightness of the object.

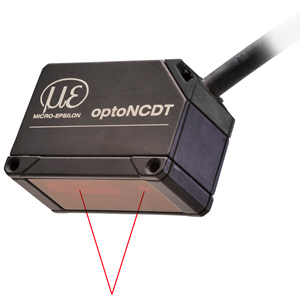

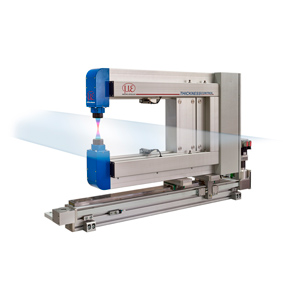

Advanced automation in the line

The optoNCDT 1900 offers a unique combination of speed, size, performance and application versatility for displacement, distance and position measurements. The compact triangulation sensor achieves high measuring accuracy and measuring rates of up to 10 kHz. The sensor's powerful optics produce a small light spot, which reliably detects even the smallest details and structures. Models with an integrated industrial Ethernet interface can be integrated into networked and virtual environments as well as the PLC. This is advantageous, for example, when detecting the electrode layer thickness in battery cell production.

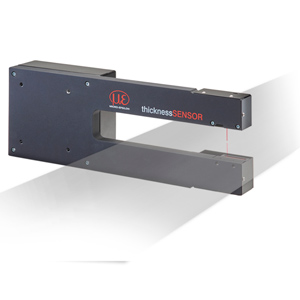

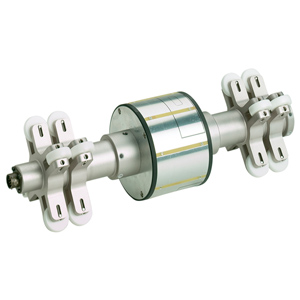

High-tech in high-precision areas

The new high-end optoNCDT 5500 series offers maximum performance in the smallest of spaces. The measuring rate is adjustable up to 75 kHz and the results are output with sub-micrometer precision. The sensors offer real-time surface compensation, which takes place directly during the measurement. This means that extremely stable results can be generated even with changing surfaces. They are used in highly dynamic processes that require very fast measurements with high accuracy. All the electronics are integrated in the compact sensor.