The new generation of high precision inline 3D measurements

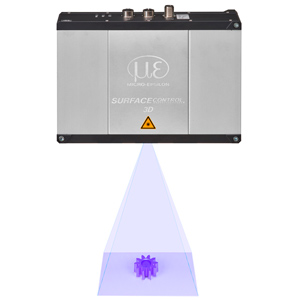

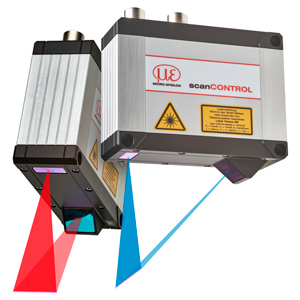

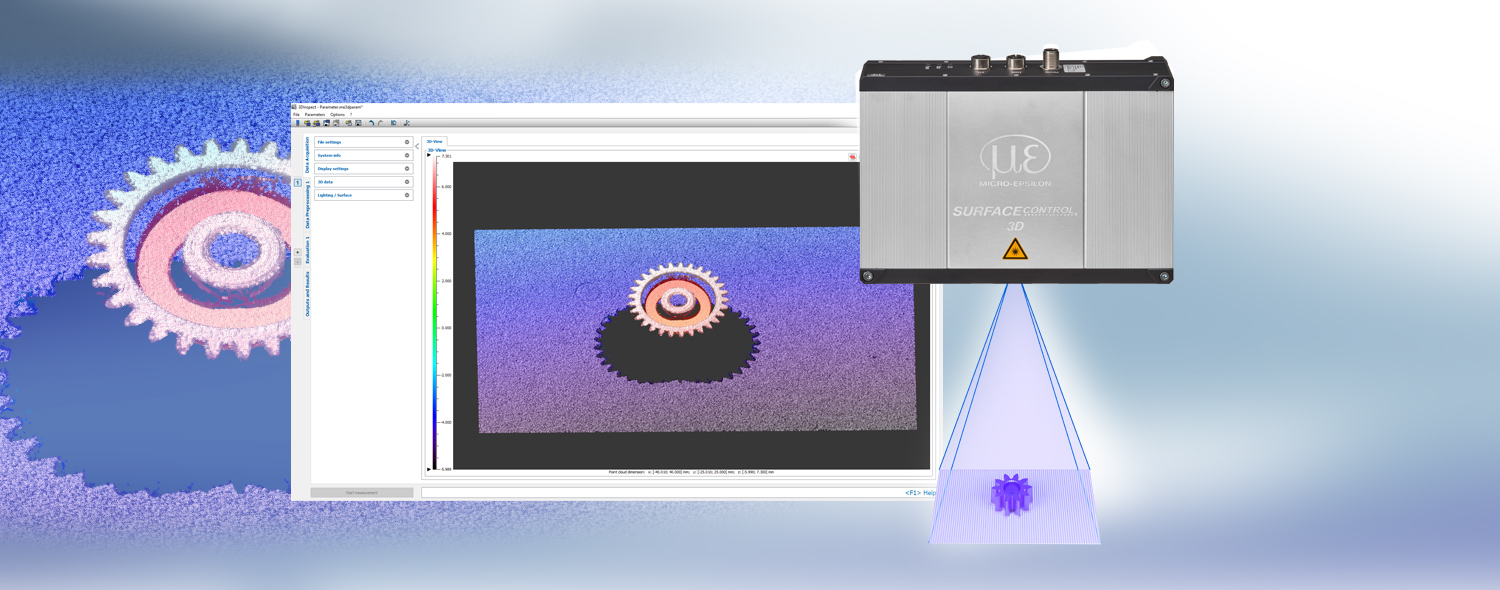

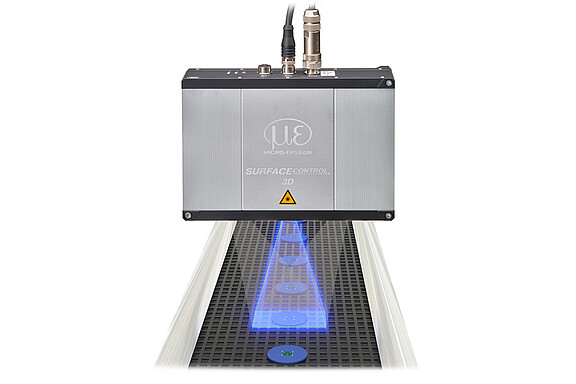

The high-precision surfaceCONTROL 3D 3500 snapshot sensor is used for the automated optical inspection of geometry, shape and surfaces on diffuse reflective surfaces. The surfaceCONTROL 3D 3500 stands out due to its compact design and high measurement accuracy combined with high data processing speed. With a z-axis repeatability up to 0.25 µm, the sensor sets new standards in high-precision inline 3D measurements. This enables reliable detection of even the smallest deviations in flatness and height. Two models cover different measuring fields.

Characteristics

- Micrometer-accurate snapshots with large measuring fields

- Fast 3D measurement from 0.2 s

- Highest precision up to 0.25 μm

- Digital interfaces (integrated): GigE Vision / GenICam

- Slim and compact sensor design

- Up to 2.2 million 3D points/second

- Digital interfaces (via 2D/3D Gateway): PROFINET / EtherCAT / EtherNet/IP*

- Digital in-/outputs: 4 digital I/Os for which parameters can be set (for external trigger, sensor control, output of sensor states)

The new generation of 3D measurements

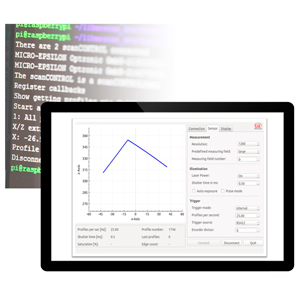

In addition to the fast data output via Gigabit Ethernet, the sensor offers an additional digital I/O interface. The 2D/3D Gateway II supports EtherNet/IP, PROFINET and EtherCAT connections. Powerful software tools enable precise 3D measurements and surface inspections. GigE Vision compatibility also allows easy integration into third-party image processing software. The comprehensive SDK for customer software integration rounds off the software package.

Application examples:

- 3D geometry inspection and form detection

- Inspection of form, position and surface

- Defect detection

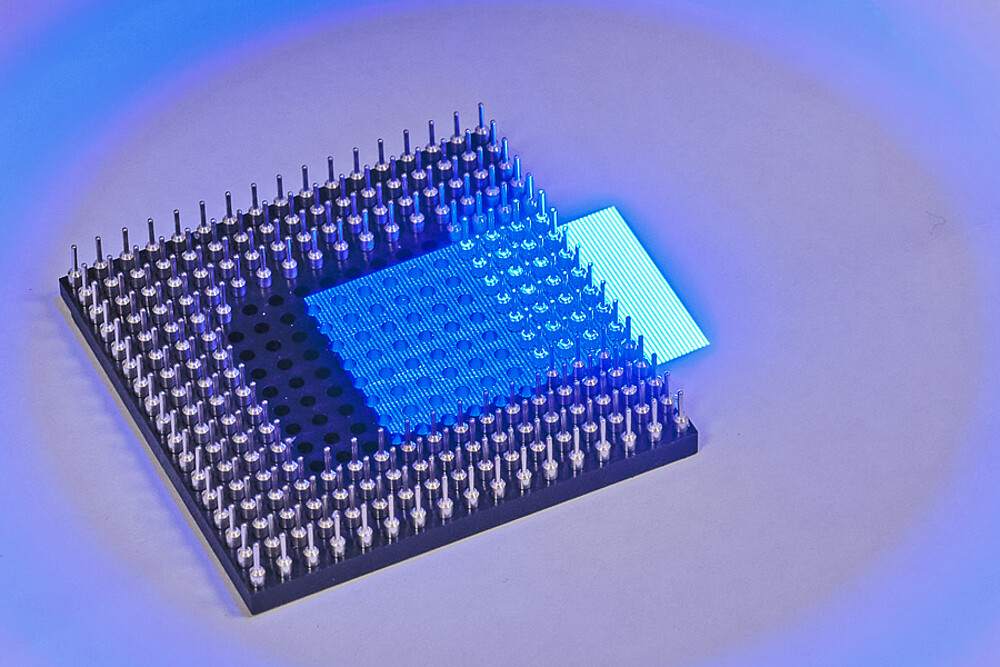

- 3D text recognition and detection of finest structures

- Inspection of electronic components

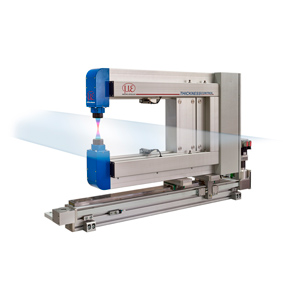

For 3D measurements with maximum precision - the surfaceCONTROL 3500-30

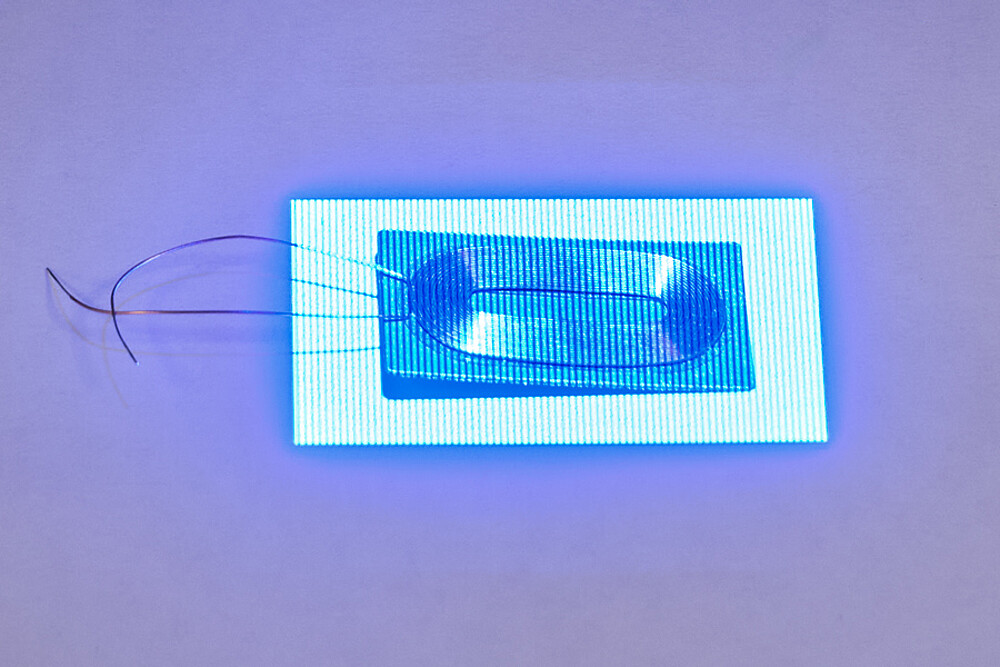

With its small measurement area of 30 x 18.5 mm, the surfaceCONTROL 35x0-30 detects the finest geometries and surface structures with utmost precision and reliability. Its high z-axis resolution and the precise repeatability make the 3D sensor the most precise on the 3D snapshot sensor market. In addition, the measuring objects are detected at a working distance of 130 mm. The high XY resolution from 8 µm allows even more precise detection of finest details.

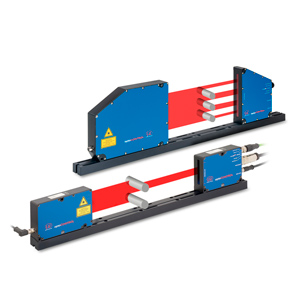

Large measurement range and excellent precision - surfaceCONTROL 3500-240

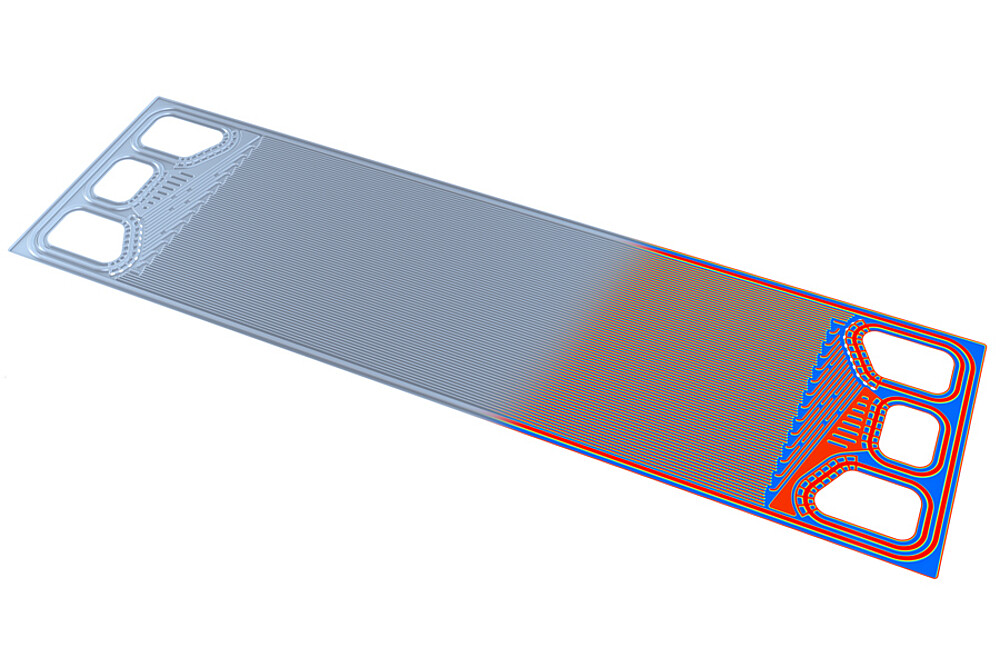

With a measurement area up to 245 x 180 mm, the surfaceCONTROL 35x0-240 captures structures and details on larger targets with high precision. Due to their high z-axis measuring range of 240 mm, the sensors are ideal for applications with large measuring volumes. Their extremely high z-axis resolution in combination with the large measurement area enables maximum precision in a wide range of applications, e.g. in testing bipolar plates for fuel cells or in robotic applications.

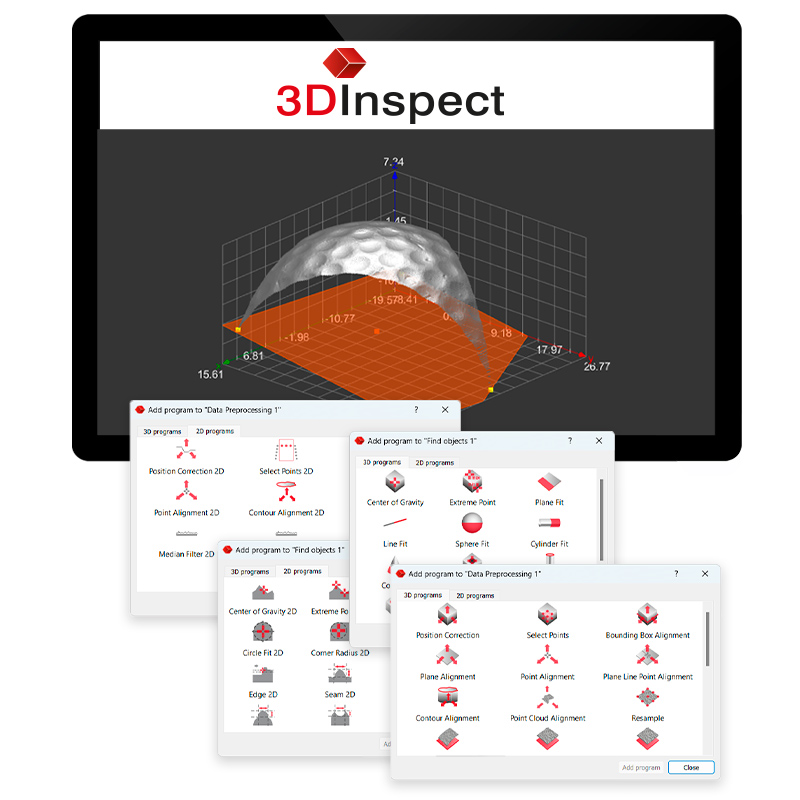

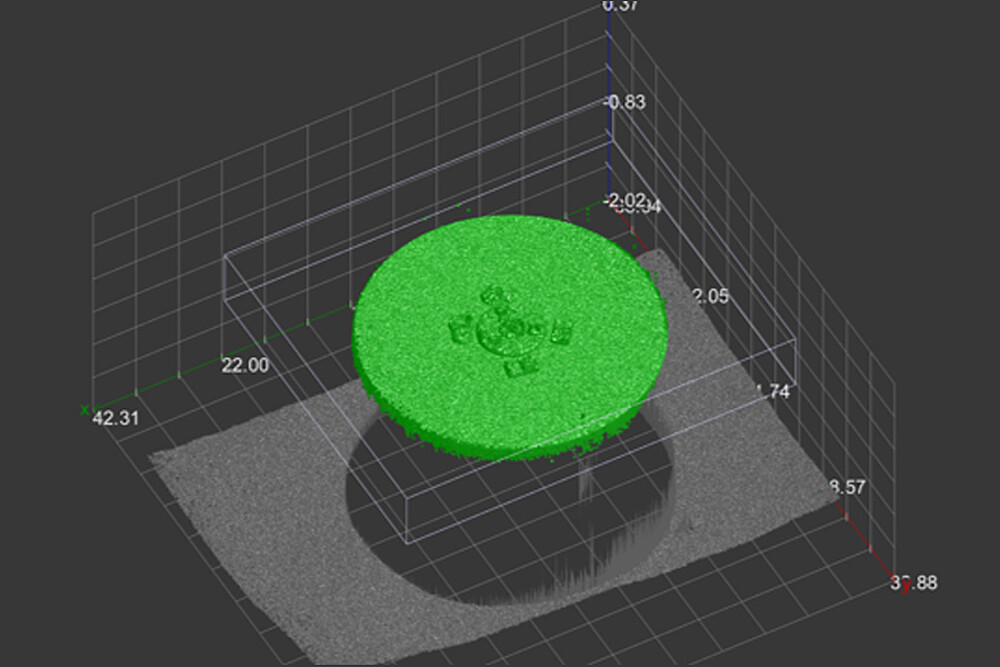

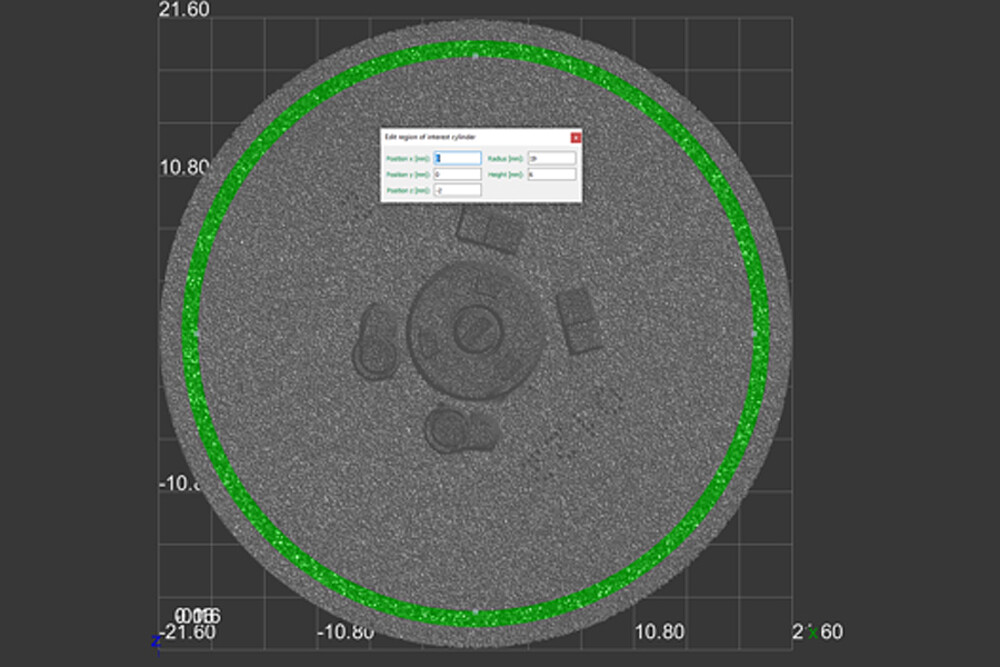

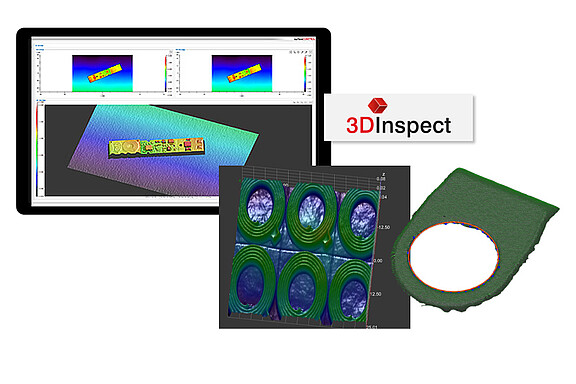

3DInspect software for 3D measurement tasks and inspection

The 3DInspect software is a powerful tool for sensor parameter set up and industrial measurement tasks. This software transmits the measurement data from the sensor via Ethernet and provides the data in three-dimensional form. This 3D data is further processed, evaluated and assessed with 3DInspect measuring programs on the PC and, if necessary, logged and transmitted via Ethernet to a control unit. If required, these 3D data can be saved with the software. Furthermore, the set up and configuration of the sensor is possible via the software. For connection to an automation interface, the functional extension 3DInspect Automation is enabled with use of the SC3510 sensors, which also includes comprehensive data logging.